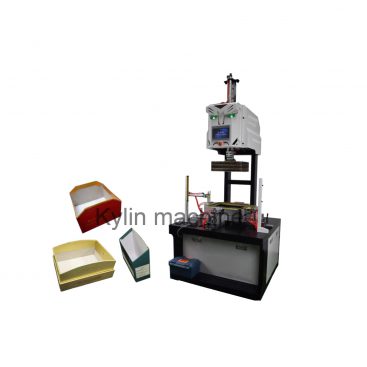

Automatic book casing-in machine function:

accurately glue the finished book core and cover together, also known as casing-in; widely used in hardcover books, notebooks and other occasions that require casing-in.

The equipment can be operated by one to two people. The operator only needs to place the book core and cover. The machine automatically sends the book core into the lifting plate for upward movement. After passing through the gluing roller, it automatically applies adhesive on both sides and combines with the cover. Then it goes through positioning pressure from above to become a finished product.

I. Main features:

1. With automatic spine positioning and pre-pressing functions: suitable for various types of covers, flat spines or round spines without changing molds, the device will press against the spine to automatically combine with the skin shell and book core. When taking out finished products, they are preliminarily glued in place without displacement of book cores.

2. Automatic mode, semi-automatic mode and manual debugging mode can be selected according to actual needs;

3. Touch screen control: function selection, parameter setting, fault prompt;

4. Driven by frequency conversion motor with adjustable speed (commonly used speed is 12 books/minute).

5.One-key lifting of glue tank for easy cleaning without removing screws.

6.One-key cleaning function: Pressing down on this button will automatically clean up water which solves problems caused by difficult manual cleaning of rollers group . During cleaning process there is no need to loosen up any glue rollers ,which saves time compared with conventional steps where you have adjust thickness every time when starting up .

7.Slow standby: When there is no operation on machine,it enters low-energy state,the gluing roller runs slowly,to prevent glue from drying out.Machine has stop,pause buttons at hand position so that you can pause or resume operation anytime easily .

8.Light grid protection for placing books,machine has emergency stop button at hand position,easy operation.

II.Operation characteristics:

1.Adjustment of Book Core Thickness:The left side & right side each have an adjustment wheel,and there’s a size digital display on them.The reading value should be adjusted half way between measured values of actual thicknesses

2.Adjustment of Book Core Width:Move limit block which places Book Core according its width

3.Adjustment of Cover Size:Put in Cover then adjust corresponding locating blocks accordingly

4.Offset between Cover & Book Core :Change coordinate values on touch screen panel 0f Machine(accuracy within 0.lmm)

5.Pause Time Setting:Set parameters such as stopping time after finishing products are made,interval pause time per book under auto-mode,sending speed,and auto-resetting etc.,freely on touch screen panel

III.Other instructions:

1.The initial position where adhesive starts applying onto upper surface of bookcore can be adjusted.It allows butterfly binding like shown below;

2.As long as thicknesses exceed 5mm,various common types of covers,flat spines or round spines type books available in market can directly use this machine,but not suitable for processing shaped-books having too many artistic surfaces。

3.No skilled operators needed.Manual placement & removals suffice.Accuracy guaranteed by machines unaffected by human shaking.Normal female workers could operate casually。

4.Glue thickness can be locked.Cleaning,stopping,reusing do not require re-adjustments(glue thickness already set before leaving factory).Simple operating procedures during start-up/shutdown。

5.Taiwan brand frequency converter;Control circuit adopts safe low voltage (24V) design;Touch screen human-machine interface;Common power cord plug-and-play makes using more convenient,safe accurate,durable.

Note:

1.The machine requires external compressed air supply.Compressed air compressor must be provided separately by user himself/herself。

2.The machines are divided into cold-glue models & hot-melt models based upon applicable adhesives.They cannot interchange(default model commonly used here is cold-glue model):

Cold Glue Model – Suitable for white glue or cold adhesives with moderate fluidity.Heated hot melt adhesives cannot work together。Hot Melt Model – Only applicable heated hot melt adhesives(jelly-like gum)。

3.Silicone rubber coating rollers、stainless steel coating rollers with patterns etc.can all be customized;

4.Other designated functions could also be customized.For example,Automatic brushing-on function at positions where Books’cores&spine meet.(There’re two situations requiring brushing-on:(a)For glued-book cores whose spine widths slightly protrude beyond their own body widths,resulting in about lmm less adhesive applied;(b)Spine-wrapped cloth fabrics absorb too much adhesive resulting insufficient amount.This kind-of-books would lack enough adhesive if not brushed-on manually before being cased-in traditionally.)

Book Casing In Machine

Specification| Model | Ky-560 |

| Glue dimension size(max) | 420*360mm |

| Glue dimension size(min) | 90*60mm |

| Book spine size | 5-65mm |

| Working speed | 650Pcs/Hour |

| Length of gluer | 420mm |

| Power supply | 220v/50Hz |

| Mainframe Power | 1.2KW |

| Machine weight | 350kg |

| Mainframe dimension | 1650*820*1780mm |

| Packaging Volume: | 3CBM |

Kylin machine company introduction

ADDITIONAL SERVICES

Customers Meeting&Machines Training

Meeting in India

Meeting in India

Meeting in Dubai

Meeting in Dubai

Trip to Turkey

Trip to Turkey

To help you master the installation and operation of your equipment, Kylin provides authorized training programmes led by surface preparation specialists.

- How to set up your machine and optimize performance levels for your process.

- Key trouble-shooting tips that keep your machine(s) in prime condition to minimize downtime, minimize maintenance, and prevent future problems.

- How to optimize performance levels to maintain consistent quality and minimize waste

- The latest legislation and how to keep the machine safe.

We offer three years machine quality warrantty, we want You to be satisfied with the work we do and our Machine,

Every time. We Guarantee to perform all good services to your complete satisfaction at the agreed upon price.

If at any time within 30 days after completion of the job you're not completely satisfied, we will Re-Clean all required areas to your satisfaction.

If you 're still not satisfied we will refund the money paid.

Help from technician is only a phone call away.

We offer free over the phone tech support to help you troubleshoot any issue you may be having.

If you require onsite help we are able to send our technicians to you! Whether it’s for training or support we can meet your needs.

Our experienced factory technicians are eager for you to get the most from your Kylin Machine.

We also offer to do regular maintenance to your machinery to make sure it stays in the best condition throughout the lifetime of the product.

This will help guarantee that your machines will work well for as long as possible.

Initially one of our experienced operators will try and help you resolve the problem over the telephone.

If that is not successful then we would send a field engineer out to site.

Our engineers carry the most common spare parts so that most problems can be repaired on site.

In the unlikely event that the machine could not be repaired on site, we would either arrange another on site visit if appropriate,

or take the machine in to our state of the art workshop where we can deal with all types of repairs and refurbishments

We're not the only ones happyexcited about KYLIN MACHINES

10,000 customers in 30 countries using KYLIN MACHINES, meet our customers

What Client’s Say

Dear Jacob,

l am writing to thank you for the recent delivery of spare parts that we ordered

from your company.We have received the shipment in good condition and are pleased with the quality of the products you provided.26 Mar 2023

The machine is working now fine , beautiful … thank you so much and maybe if we need other kind of box making machines I will contact you

Hi Jacob, thanks and i let you know…

Bit until now everythimg is perfect!Mit den besten Grüßen,

28 April 2023

We had purchased two paper bag machines from Kylin last 3 year, untill now, the machines is using very well, and help us a lot in making luxury paper bag. Thanks Kylin DEM IMPEX PRIVATE LIMITED

We have purchased case maker Ky-450 last year 2013, right now the machine is running very stable, we are going to order one more machine from Kylin.

EVER OLIVIA ENTERPRISE CO.,LTD

We are the Agent of Kylin machine in UK, ky-40 Box stay machine and Ky-500 is very good comments, choose Kylin machine, choose the good quality Thanks

Good Morning JacobBusiness is going well!Your box corner taper has been running like a champion saving us time and money!!As we continue to grow we will definitely keep in touch and see if we can continue to our relationship with Kylin MachinesAll the best!!Jason