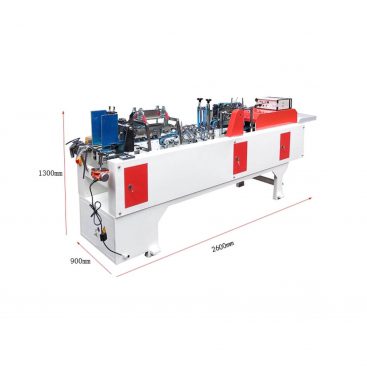

Cardboard Cutting Machine, board cutter, Gray board Slitting machine mainly used for cutting the big size cardboard materials into small size. It can be used to cut grey board, chipboard, paper board, industry grey board etc. Cardboard cutter machine is a necessary equipment for the production of hardcovers, book covers, note book cover, box file, rigid boxes, package cases etc.

Features:

1. Feeding large size cardboard and then turn into small size cardboard automatically. Servo controlled.

2. Pneumatic cylinders control the pressure, easy adjustment of cardboard thickness.

3. The safety cover is designed according to European CE standard.

4. Adopt the concentrated lubrication system, easy to maintain.

5. Main structure is made of casting iron, stable without bending.

6. The crusher cuts the waste into small pieces and discharges them with conveyor belt.

1) Auto feeder It adopts bottom-drawn feeder which feeding the material without stopping. It’s available to feed small size of board automatically.

2) 8 sets of High Quality knives Adopt alloy round knives which reduce the abrasion and improve the cutting efficiency.

3) CE standard safety cover The safety cover is designed according to the CE standard which efficiently prevents the disoperation and ensures the personal safety.

4) Pneumatic pressure control device Adopt air cylinders for the pressure control which reduce the operational requirement for workers.

5) Servo and Ball Screw The feeders are controlled by the ball screw, driven by the servo motor which efficiently improves the precision and makes adjustment easy.

6) Auto knife distance setting According to the setting, the guide will automatically move to the position.

7) Waste crusher The waste will be automatically crushed and collected when cutting the large sheet of cardboard.

Cardboard Slitting Machine

Specification| Model | Ky-1300 |

| Cardboard width | W≤1300mm, L≤1300mm |

| Cardboard thickness | 1-3mm |

| Production speed | ≤60m/min |

| Motor power | 1.5kw/380v 3phase |

| Machine Weight | 1250kg |

| Machin dimension | 2000X1200X1100 (mm) |

Kylin machine company introduction

ADDITIONAL SERVICES

Customers Meeting&Machines Training

Meeting in India

Meeting in India

Meeting in Dubai

Meeting in Dubai

Trip to Turkey

Trip to Turkey

To help you master the installation and operation of your equipment, Kylin provides authorized training programmes led by surface preparation specialists.

- How to set up your machine and optimize performance levels for your process.

- Key trouble-shooting tips that keep your machine(s) in prime condition to minimize downtime, minimize maintenance, and prevent future problems.

- How to optimize performance levels to maintain consistent quality and minimize waste

- The latest legislation and how to keep the machine safe.

We offer three years machine quality warrantty, we want You to be satisfied with the work we do and our Machine,

Every time. We Guarantee to perform all good services to your complete satisfaction at the agreed upon price.

If at any time within 30 days after completion of the job you're not completely satisfied, we will Re-Clean all required areas to your satisfaction.

If you 're still not satisfied we will refund the money paid.

Help from technician is only a phone call away.

We offer free over the phone tech support to help you troubleshoot any issue you may be having.

If you require onsite help we are able to send our technicians to you! Whether it’s for training or support we can meet your needs.

Our experienced factory technicians are eager for you to get the most from your Kylin Machine.

We also offer to do regular maintenance to your machinery to make sure it stays in the best condition throughout the lifetime of the product.

This will help guarantee that your machines will work well for as long as possible.

Initially one of our experienced operators will try and help you resolve the problem over the telephone.

If that is not successful then we would send a field engineer out to site.

Our engineers carry the most common spare parts so that most problems can be repaired on site.

In the unlikely event that the machine could not be repaired on site, we would either arrange another on site visit if appropriate,

or take the machine in to our state of the art workshop where we can deal with all types of repairs and refurbishments

We're not the only ones happyexcited about KYLIN MACHINES

10,000 customers in 30 countries using KYLIN MACHINES, meet our customers

What Client’s Say

Dear Jacob,

l am writing to thank you for the recent delivery of spare parts that we ordered

from your company.We have received the shipment in good condition and are pleased with the quality of the products you provided.26 Mar 2023

The machine is working now fine , beautiful … thank you so much and maybe if we need other kind of box making machines I will contact you

Hi Jacob, thanks and i let you know…

Bit until now everythimg is perfect!Mit den besten Grüßen,

28 April 2023

We had purchased two paper bag machines from Kylin last 3 year, untill now, the machines is using very well, and help us a lot in making luxury paper bag. Thanks Kylin DEM IMPEX PRIVATE LIMITED

We have purchased case maker Ky-450 last year 2013, right now the machine is running very stable, we are going to order one more machine from Kylin.

EVER OLIVIA ENTERPRISE CO.,LTD

We are the Agent of Kylin machine in UK, ky-40 Box stay machine and Ky-500 is very good comments, choose Kylin machine, choose the good quality Thanks

Good Morning JacobBusiness is going well!Your box corner taper has been running like a champion saving us time and money!!As we continue to grow we will definitely keep in touch and see if we can continue to our relationship with Kylin MachinesAll the best!!Jason