Why Is High-End Cardboard Packaging Becoming the Game-Changer for Premium Brands?

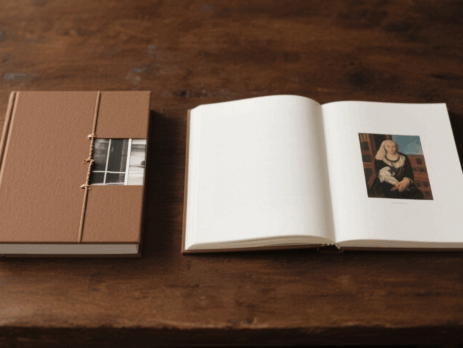

Brands struggle to stand out. Generic packaging floods the market. Customers scroll past without noticing. High-end cardboard packaging transforms ordinary products into premium experiences through advanced customization, sustainable materials, and innovative finishing techniques. Companies like Tipomar Packaging demonstrate how rigid box machines and specialized equipment create packaging that drives brand...