How Do You Make a Rigid Box That Stands Out in Today’s Market?

You walk into a luxury store and see beautiful packaging that makes you want to touch it. That’s the power of rigid boxes. They grab attention and make customers feel special.

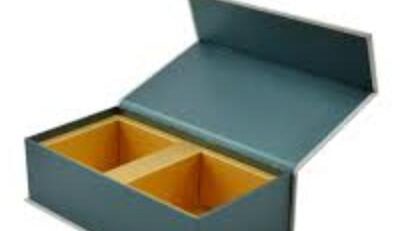

Rigid boxes are premium packaging made from thick chipboard wrapped in decorative paper. They offer superior protection and create an unforgettable unboxing experience that turns ordinary products into luxury items.

I’ve been in the packaging machinery business for over 20 years. I’ve seen how the right rigid box can transform a brand’s image overnight.

What Makes Rigid Box Manufacturing So Complex?

You might think making a box is simple. But rigid boxes are different. They need precision and skill that most people don’t understand.

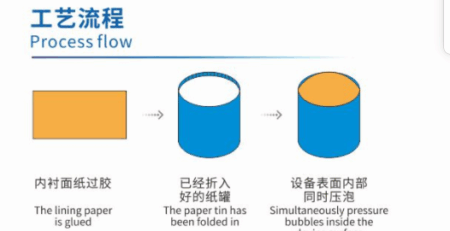

Rigid box manufacturing involves six critical steps: creating dieline templates, prototyping, cutting chipboard, assembly, wrapping, and quality control. Each step requires specialized machinery and expertise to ensure premium results.

At Kylin Machine, we’ve perfected this process. Our Ky-500 rigid box machine handles the most demanding production requirements. The machine uses thick chipboard, typically 2-3mm, which provides the strength that makes rigid boxes special.

| Manufacturing Step | Manual Process Time | Machine Process Time | Quality Consistency |

|---|---|---|---|

| Dieline Creation | 2-3 hours | 30 minutes | High with CAD |

| Cutting & Scoring | 1 hour per batch | 10 minutes per batch | Excellent |

| Assembly | 45 minutes per box | 5 minutes per box | Superior |

| Wrapping | 30 minutes per box | 3 minutes per box | Perfect |

The difference between partial finish and full finish boxes matters more than you think. Partial finish boxes show some chipboard inside. Full finish boxes cover everything with decorative paper. I always recommend full finish for luxury products because customers notice these details.

Our customers in the Middle East and Europe tell me the same thing. When they switched to automated rigid box production, their quality improved and costs dropped. The Ky-430A auto rigid box machine can produce 600-800 boxes per hour with consistent quality.

Watch our rigid box machine demonstration

Why Do Luxury Brands Choose Rigid Boxes Over Other Options?

You see rigid boxes everywhere in high-end retail. There’s a reason for this. They create emotional connections that other packaging can’t match.

Rigid boxes offer superior durability, premium aesthetics, and reusability that folding cartons and corrugated boxes cannot provide. They protect valuable products while creating a luxury unboxing experience that enhances brand perception.

I remember visiting a jewelry manufacturer in Italy. They showed me two identical necklaces. One came in a folding carton, the other in a rigid box. The rigid box version sold for 30% more. The product was the same, but the packaging changed everything.

Rigid boxes come in many styles. Telescope boxes have lids that cover the base completely or partially. Hinged lid boxes open like books. Magnetic closure boxes use strong magnets for a satisfying snap. Each style serves different products and creates different experiences.

| Box Style | Best For | Customer Appeal | Production Complexity |

|---|---|---|---|

| Telescope | Electronics, cosmetics | High | Medium |

| Hinged Lid | Jewelry, gifts | Very High | High |

| Magnetic Closure | Premium items | Excellent | High |

| Drawer Style | Watches, accessories | High | Medium |

The materials matter too. We use specialty papers, fabric, or even leather for wrapping. Finishing techniques like foil stamping, embossing, and UV coating add luxury touches. Our Ky-530A edge gilding machine creates beautiful metallic edges that customers love.

Inserts play a crucial role. Custom foam, molded pulp, or paperboard inserts keep products secure and create organized presentations. The right insert turns opening a box into an event.

What Are the Real Challenges in Rigid Box Production?

You need to understand the difficulties before starting rigid box production. Many companies fail because they underestimate the complexity.

Rigid box production faces challenges including high material costs, longer production times, size limitations, and the need for specialized equipment. Success requires proper machinery, skilled operators, and quality control systems.

Cost is the biggest challenge. Rigid boxes cost 3-5 times more than folding cartons. The thick chipboard, specialty papers, and complex assembly process drive up expenses. But customers pay premium prices for products in rigid boxes, so the investment often pays off.

Production time is another issue. Making rigid boxes takes 1-2 weeks longer than other packaging. Each box requires individual assembly and wrapping. Automation helps, but you still need skilled workers for quality finishing.

Size limitations surprise many people. Large rigid boxes become less durable because the wrapping paper can tear under stress. We recommend using thicker papers and laminated finishes for boxes over 300mm in any dimension.

| Challenge | Impact Level | Solution | Investment Required |

|---|---|---|---|

| High Costs | High | Automation, bulk materials | $50,000-200,000 |

| Long Production Time | Medium | Efficient workflow, training | $10,000-30,000 |

| Size Limitations | Low | Better materials, design | $5,000-15,000 |

| Quality Control | High | Inspection systems | $20,000-50,000 |

Quality control becomes critical with rigid boxes. Customers expect perfection when they pay premium prices. Every corner must be sharp, every surface smooth, every finish flawless. Our quality control systems catch defects before boxes reach customers.

I’ve helped over 2,500 companies worldwide set up rigid box production. The successful ones invest in proper equipment from the start. They don’t try to cut corners on machinery or training. The Ky-500A rigid box forming machine includes built-in quality monitoring that prevents most common problems.

See our complete rigid box production line

Conclusion

Rigid boxes transform ordinary products into luxury experiences through superior materials, precise manufacturing, and attention to detail.

About me:

I’m Jacob from Kylin Machine, specializing in post-press machinery for rigid box production. Our factory in Dongguan has served over 10,000 customers in 20+ countries since 2003, providing advanced robotic spotter and hybrid solutions for rigid box and hard book cover applications.

发表回复