What is a Rigid Box Machine?

Your packaging looks cheap, and customers are noticing. You need a solution that screams quality, but where do you start?

A rigid box machine is specialized equipment designed to automate the production of high-quality, sturdy boxes, often used for luxury goods, electronics, and gift packaging. These machines streamline the process, ensuring consistency and efficiency.

Feeling overwhelmed by packaging choices? Let’s break down what makes rigid boxes, and the machines that create them, a game-changer for businesses like yours. I’ve been in this industry for years, and I’ve seen firsthand how the right packaging can elevate a brand. It’s not just about a box; it’s about the experience you deliver to your customers. At Kylin Machine, we’ve dedicated ourselves to perfecting this craft.

What is a rigid box?

Are your products getting damaged in flimsy packaging? Do you want a premium feel that reflects your brand’s quality?

A rigid box, also known as a set-up box, is a type of packaging made from thick paperboard, offering superior strength and a luxurious feel. Unlike folding cartons, they are typically delivered pre-assembled and ready to use.

When I first started in the packaging industry, I was amazed by the difference a rigid box could make. It’s not just about protection; it’s about presentation. Think about unboxing a high-end smartphone or a piece of jewelry. That satisfying, sturdy feel? That’s often a rigid box. They are constructed from a non-bending chipboard, which is then wrapped with paper or other materials. This construction gives them their characteristic strength and premium appearance. For businesses in the graphic arts, paper converting, and bookbindery industries, understanding the nuances of rigid boxes is crucial. Many of our clients at Kylin Machine come to us specifically because they want to produce packaging that conveys luxury and durability. We’ve helped countless businesses, from small workshops to large enterprises, transition to using rigid boxes, and the feedback is always overwhelmingly positive. The perceived value of their products increases, and their brand image is enhanced. It’s a smart investment that pays off in customer satisfaction and brand loyalty. Our rigid box machines are designed to produce these boxes with precision and efficiency, ensuring that every box meets the highest standards.

What is the difference between rigid and corrugated boxes?

Confused about whether to choose rigid or corrugated boxes for your products? Worried about making the wrong, costly decision?

Rigid boxes offer a premium, non-collapsible structure ideal for luxury items, while corrugated boxes, made with fluted paper, provide excellent cushioning and are better suited for shipping and protecting heavier goods.

I often get asked this question by clients. It’s a common point of confusion, but the differences are quite significant. Corrugated boxes are what you typically see for shipping – think of an Amazon box. They have that wavy layer of paper (the flute) sandwiched between two flat linerboards. This design makes them strong, lightweight, and great for absorbing impacts during transit. They are also generally more cost-effective for bulk shipping. Rigid boxes, on the other hand, are all about that premium feel. They don’t have the fluting; instead, they use a dense paperboard that doesn’t bend easily. This makes them incredibly sturdy and gives them a smooth, high-end finish. They are perfect for products where presentation is key – luxury cosmetics, electronics, high-end confectionery, or gift sets. At Kylin Machine, our focus is on equipment for rigid boxes because we specialize in helping businesses create that premium unboxing experience. While corrugated boxes serve an important purpose, rigid boxes cater to a different market segment, one that values aesthetics and perceived quality. Understanding this distinction is vital for choosing the right packaging for your specific product and brand strategy.

| Feature | Rigid Box | Corrugated Box |

|---|---|---|

| Material | Dense paperboard (chipboard) | Fluted paper between linerboards |

| Structure | Non-collapsible, sturdy | Often collapsible, good cushioning |

| Appearance | Premium, smooth finish | More utilitarian, can be printed |

| Primary Use | Luxury goods, gift packaging, presentation | Shipping, protecting heavier items |

| Cost | Generally higher | Generally lower, especially in bulk |

| Customization | High (wraps, finishes, inserts) | Moderate (printing, die-cutting) |

What is a box machine?

Are manual box-making processes slowing you down and leading to inconsistencies? Do you need to scale up production without sacrificing quality?

A box machine is automated or semi-automated equipment designed to perform various stages of box manufacturing, such as cutting, creasing, folding, gluing, and wrapping, significantly increasing production speed and consistency.

When we talk about a "box machine," it’s a broad term. It can range from a simple manual die-cutter to a fully automated production line. At Kylin Machine, we specialize in machines for rigid boxes. These aren’t just any box machines; they are sophisticated pieces of engineering designed for precision and efficiency. For example, our Robotic Spotter and Hybrid machines are at the forefront of technology for rigid box and hard book cover solutions. These machines can handle complex tasks like accurately placing magnets (see our magnet pasting machines), forming intricate shapes, and applying various wraps with incredible speed and precision. Before I founded Kylin Machine in 2003, I saw many businesses struggling with manual or outdated processes. The quality was inconsistent, and they couldn’t keep up with demand. That’s why we focused on developing advanced machinery. A good box machine doesn’t just make boxes; it solves problems. It helps businesses reduce labor costs, minimize material waste, improve product quality, and increase output. For our customers in the graphic arts and paper converting industries, investing in the right box machine is a critical step towards growth and profitability. It allows them to take on more complex jobs and serve a wider range of clients.

How to manufacture rigid boxes?

Wondering about the intricate process behind creating those elegant rigid boxes? Curious how technology can transform raw materials into premium packaging?

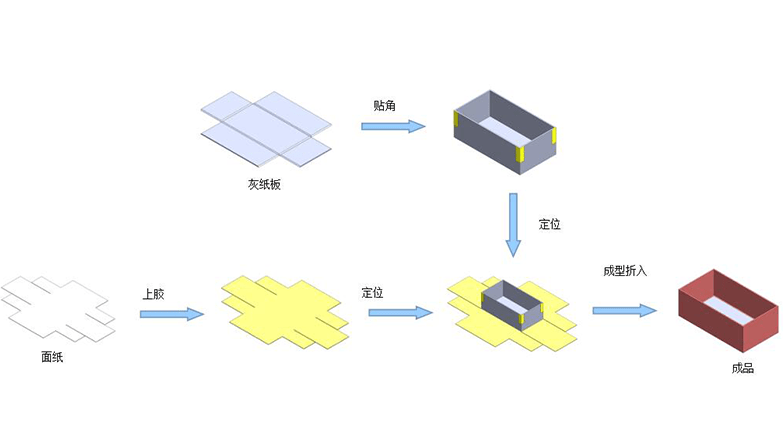

Manufacturing rigid boxes involves several key steps: cutting and scoring the paperboard (using grooving machines), forming the box structure (with box forming machines), and then wrapping it with a decorative paper or material (using box wrapping machines), often automated by specialized machinery for precision and efficiency.

The journey of a rigid box from raw material to finished product is fascinating. It starts with the core material, typically a thick chipboard. First, this chipboard is precisely cut and scored. The scoring creates the lines along which the board will be folded to form the box shape. This step is critical for accuracy; even a small error can affect the final box. Next, the corners of the cut chipboard are often V-grooved (with a V-grooving machine) or stayed (taped with a corner pasting machine) to create sharp, clean edges when the box is formed. Then, the flat, scored chipboard is formed into its three-dimensional shape. This might involve folding up the sides and securing them. The real magic, and where Kylin Machine’s expertise shines, often comes in the wrapping stage. A decorative paper, fabric, or other material is meticulously applied to the exterior (and sometimes interior) of the formed chipboard shell. This requires precise glue application (see our gluing machines) and careful positioning of the wrap to ensure a smooth, bubble-free finish. Our machines, like the KY-430A auto rigid box machine, automate these processes. They can handle everything from glue application and board positioning to wrapping and pressing, ensuring each box is perfectly made. For more complex designs, like those with magnetic closures or intricate inserts, additional steps and specialized modules are integrated into the production line. It’s a blend of robust engineering and delicate precision, all aimed at creating a box that not only protects but also impresses.

Key Stages in Rigid Box Manufacturing:

- Material Selection: Choosing the right chipboard thickness and wrap material.

- Insight: The choice of material directly impacts the box’s sturdiness and final aesthetic. Kylin Machine can advise on suitable materials for your product needs.

- Cutting and Scoring/Grooving: The chipboard is cut to size and scored or V-grooved for folding.

- Insight: Precision here is paramount. Our grooving machines ensure accuracy to fractions of a millimeter.

- Corner Staying/Taping (Optional but common): Corners are reinforced with tape for stronger joints.

- Insight: This adds durability, especially for larger boxes. Kylin offers corner taping solutions.

- Box Forming: The scored chipboard is folded and assembled into the basic box shape.

- Insight: Automated forming ensures consistency and speed, which our box formers excel at.

- Glue Application: Adhesive is applied to the wrap material or the box shell.

- Insight: Even and precise glue application is key to a good finish, a feature of Kylin gluers.

- Wrapping: The decorative wrap is applied to the chipboard shell.

- Insight: This is where the visual appeal comes in. Our robotic spotters ensure perfect wrap alignment.

- Pressing/Finishing: The wrapped box is pressed to ensure adhesion and a smooth finish.

- Insight: Proper pressing (using pressing machines) eliminates air bubbles and ensures a durable bond.

Conclusion

Rigid box machines are essential for creating premium packaging. Kylin Machine offers advanced solutions to elevate your brand and meet your production needs efficiently.

Jacob

www.kylinmachines.com

Kylin Machine, China

Specializing in Robotic Spotter and Hybrid technology for rigid box and hard book cover solutions.

发表回复