This fully automatic intelligent Jewerly box making machine is our latest R&D product. It is suitable for the mass production of various types of complicated boxes,such as jewelry box, gift box, slanting box, shoulder box, perfume box and slipcase. It has a wider box making range and can better meet the needs of the modern packaging market. The whole machine has a new design, which is safer and more beautiful.

Features

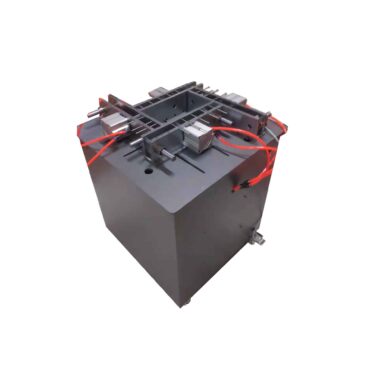

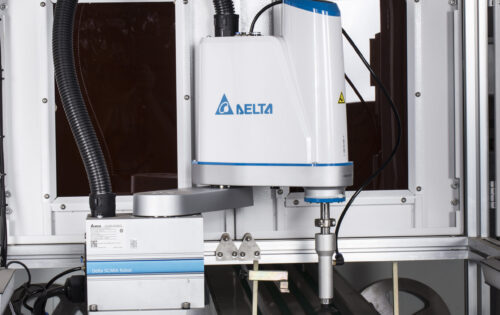

- The machine adopts a servo control system, image vision + robotic arm positioning system, which can automatically complete the feeding, gluing, positioning, box holding, edge wrapping, ear folding and folding into shape(4, 8 side box shapes with slanting shape)

- The machine uses a double-servo cam flying, double-paper table lifting and gluing system;

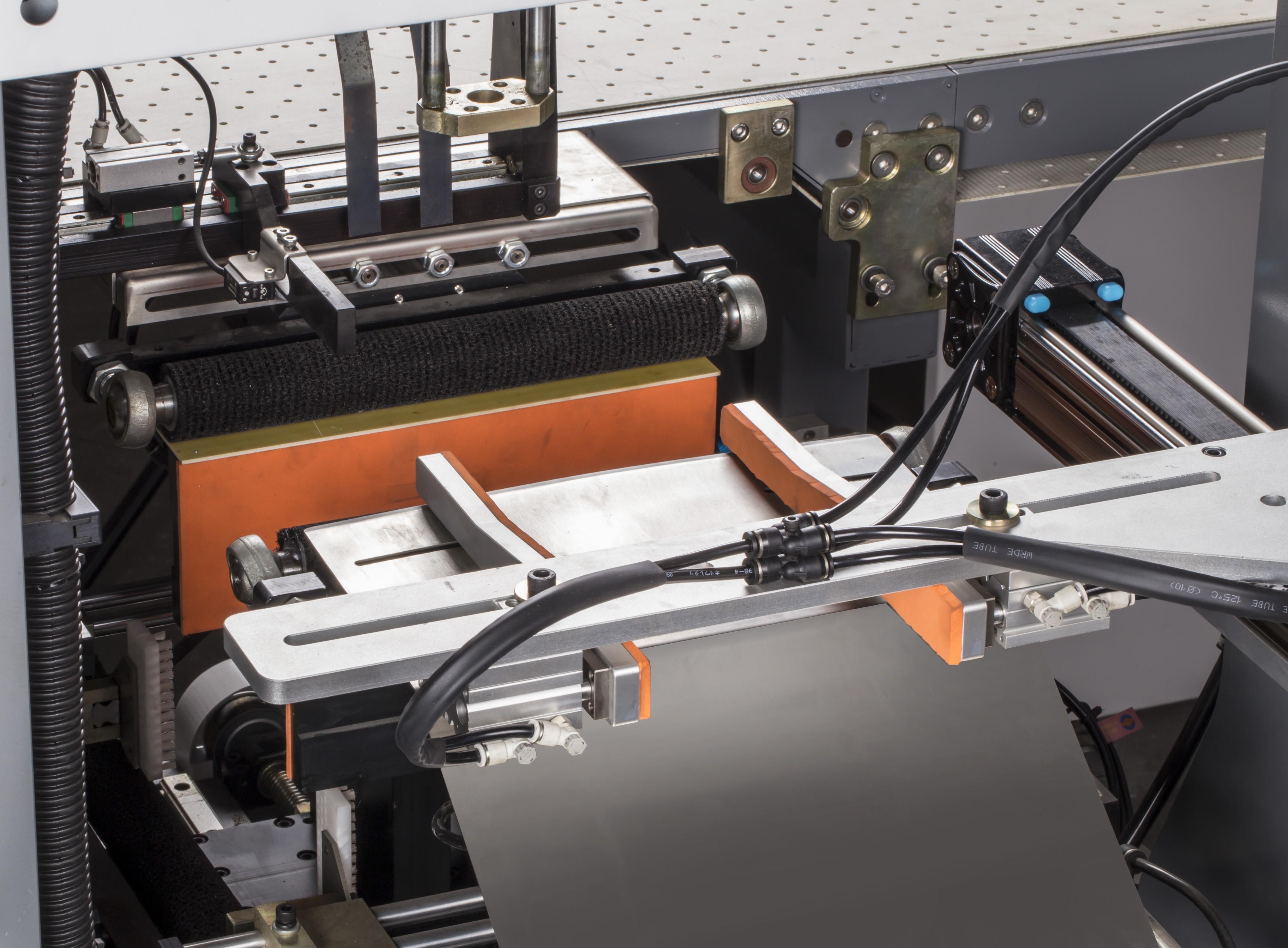

- The visual positioning system has been upgraded for many years, and the simplified template grabbing and alignment debugging are more convenient, and the positioning and version change can be completed in 5 minutes.

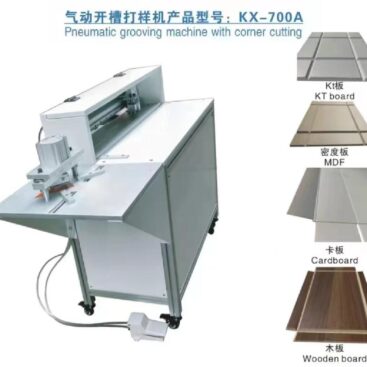

- The forming machine adopts linear guide and electronic cam drive, which is more stable and wear-resistant, and the movement is smoother. The folding depth and ear length size range are also larger; the forming adopts double-layer scraper folding and pressing and forming, and the version change can be as fast as 15 minutes.

Benefits

- The machine can improve the production efficiency and reduce the labor cost.

- The machine can improve the product quality and reduce the defective rate.

- The machine can save space and improve the working environment.

Applications

The machine is widely used in the packaging industry, such as:

- Electronics industry: mobile phone boxes, watch boxes, etc.

- Gift industry: jewelry boxes, cosmetic boxes, etc.

- Food industry: tea boxes, wine boxes, etc.

- Luxury packaging industries: perfume boxes, slipcase boxes, etc.

Fully Auto Jewelry box machine

Specification| Model | Ky-320A |

|---|---|

| Max box size | 300X200X100mm |

| Min box size | 45X45X10mm |

| Max paper size | 540X420mm |

| Min paper size | 100X60mm |

| Conveyor belt width | 540mm |

| Power | 13Kw |

| Valtage | 380V |

| Working speed | 30pcs/Min |

| Machine dimension | 4770X4300X2600mm |

| Machine weight | 3800Kg |

| Glue type | Cold/Hot glue |

Kylin machine company introduction

ADDITIONAL SERVICES

Customers Meeting&Machines Training

Meeting in India

Meeting in India

Meeting in Dubai

Meeting in Dubai

Trip to Turkey

Trip to Turkey

To help you master the installation and operation of your equipment, Kylin provides authorized training programmes led by surface preparation specialists.

- How to set up your machine and optimize performance levels for your process.

- Key trouble-shooting tips that keep your machine(s) in prime condition to minimize downtime, minimize maintenance, and prevent future problems.

- How to optimize performance levels to maintain consistent quality and minimize waste

- The latest legislation and how to keep the machine safe.

We offer three years machine quality warrantty, we want You to be satisfied with the work we do and our Machine,

Every time. We Guarantee to perform all good services to your complete satisfaction at the agreed upon price.

If at any time within 30 days after completion of the job you're not completely satisfied, we will Re-Clean all required areas to your satisfaction.

If you 're still not satisfied we will refund the money paid.

Help from technician is only a phone call away.

We offer free over the phone tech support to help you troubleshoot any issue you may be having.

If you require onsite help we are able to send our technicians to you! Whether it’s for training or support we can meet your needs.

Our experienced factory technicians are eager for you to get the most from your Kylin Machine.

We also offer to do regular maintenance to your machinery to make sure it stays in the best condition throughout the lifetime of the product.

This will help guarantee that your machines will work well for as long as possible.

Initially one of our experienced operators will try and help you resolve the problem over the telephone.

If that is not successful then we would send a field engineer out to site.

Our engineers carry the most common spare parts so that most problems can be repaired on site.

In the unlikely event that the machine could not be repaired on site, we would either arrange another on site visit if appropriate,

or take the machine in to our state of the art workshop where we can deal with all types of repairs and refurbishments

We're not the only ones happyexcited about KYLIN MACHINES

10,000 customers in 30 countries using KYLIN MACHINES, meet our customers

What Client’s Say

Dear Jacob,

l am writing to thank you for the recent delivery of spare parts that we ordered

from your company.We have received the shipment in good condition and are pleased with the quality of the products you provided.26 Mar 2023

The machine is working now fine , beautiful … thank you so much and maybe if we need other kind of box making machines I will contact you

Hi Jacob, thanks and i let you know…

Bit until now everythimg is perfect!Mit den besten Grüßen,

28 April 2023

We had purchased two paper bag machines from Kylin last 3 year, untill now, the machines is using very well, and help us a lot in making luxury paper bag. Thanks Kylin DEM IMPEX PRIVATE LIMITED

We have purchased case maker Ky-450 last year 2013, right now the machine is running very stable, we are going to order one more machine from Kylin.

EVER OLIVIA ENTERPRISE CO.,LTD

We are the Agent of Kylin machine in UK, ky-40 Box stay machine and Ky-500 is very good comments, choose Kylin machine, choose the good quality Thanks

Good Morning JacobBusiness is going well!Your box corner taper has been running like a champion saving us time and money!!As we continue to grow we will definitely keep in touch and see if we can continue to our relationship with Kylin MachinesAll the best!!Jason