How are rigid paper boxes manufactured?

Rigid boxes are a staple in premium packaging, known for their durability and aesthetics. But how are they made? Let’s explore the process and materials behind rigid paper boxes.

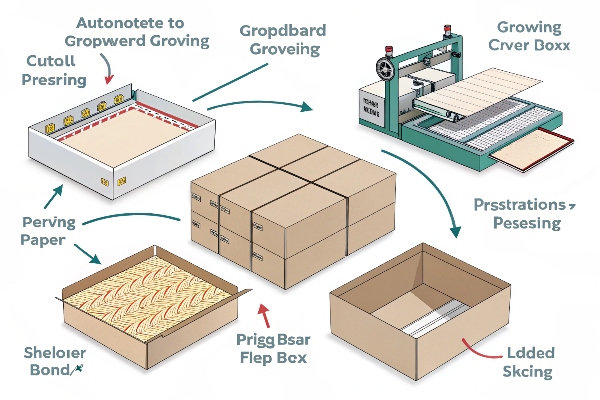

Rigid paper boxes are manufactured using specialized machinery that combines wrapping and gluing techniques1. This process involves precise cutting, scoring, folding, and assembly to achieve clean right angles and a sturdy structure2. The use of groove machines drastically improves the appearance, creating crisp edges3.

Rigorous precision and quality control are essential in rigid box manufacturing. These steps ensure the boxes meet industry standards and provide a flawless finish for high-end products.

How to manufacture rigid boxes?

Packaging solutions start with understanding what rigid boxes entail and how to manufacture them effectively. Let’s break down the manufacturing process for these sturdy containers.

Manufacturing rigid boxes involves various steps including die-cutting, gluing, and assembling. With advanced machines, manufacturers can efficiently produce high-quality boxes with consistent dimensions and appealing aesthetics1. The process also includes the application of decorative paper or fabric covering for a refined finish.

!

Advanced machinery plays a pivotal role in producing rigid boxes. Machines like the KY-430A auto rigid box machine enhance productivity with automation while ensuring precision1. This involves cutting, gluing, and assembling components to create sturdy boxes.

What are rigid boxes made of?

The manufacturing process is crucial, but what materials make rigid boxes stand out? Let’s delve into the core components used in these boxes.

Rigid boxes are made of high-quality paperboard, which offers strength and stability. This material is often covered with decorative paper, fabric, or leather to enhance visual appeal4. It’s a popular choice in luxury packaging due to its durability and customizability.

Paperboard is the primary material, providing a strong base for rigidity. Cover materials vary based on design preferences, offering flexibility and customization to suit different brands4.

How are paper boxes made?

Understanding the broader scope of paper box manufacturing helps grasp rigid box production. What are the steps involved in creating paper boxes?

Paper boxes are crafted through a series of steps including die-cutting, folding, and gluing. This process begins with selecting sturdy paperboard, followed by cutting to specific dimensions, which are then assembled into box shapes5. Rigid boxes add an extra layer of covering for premium finishes4.

Paper boxes start with high-quality paperboard, which is then cut, folded, and glued to form the box. Additional processes such as printing or embossing can further elevate the look5.

Why are rigid boxes expensive?

Rigid boxes are often more expensive than their foldable counterparts. Let’s explore the factors contributing to their cost.

Rigid boxes are costly due to their complex manufacturing process and premium materials. They require precise machinery, skilled labor, and high-quality materials, such as decorative wraps that enhance visuals14. These factors combined elevate both production costs and retail prices.

The expense arises from quality and precision needs. Advanced technologies and materials ensure rigid boxes meet high standards, which in turn increases their market value4.

Conclusion

Rigid boxes are meticulously crafted using high-quality paperboard and sophisticated machinery. Their manufacture involves precise cutting, gluing and assembly, making them ideal for luxury packaging.

发表回复