How Can Choosing the Right Box Making Equipment Help Meet Sustainable Packaging Goals?

Struggling to meet sustainability targets? Packaging is a big factor, but changing it feels complex and costly. Investing in the right box-making equipment is your key to greener packaging.

Choosing efficient, modern box-making machinery is crucial for sustainability. It allows you to use eco-friendly materials effectively, minimize waste through precision, reduce energy consumption, and create optimized packaging designs, directly supporting your environmental goals.

Making the switch to sustainable packaging feels like a huge mountain to climb, doesn’t it? You know it’s important for the planet and for your brand image, but figuring out how seems complicated. The good news is, the machinery you use plays a massive role, and upgrading can make sustainability achievable and even efficient. Let’s break down how the right equipment, like the kind we build here at Kylin Machine, makes a real difference. It’s about more than just the materials; it’s about how smartly you use them.

How to choose sustainable packaging?

Choosing eco-friendly packaging feels overwhelming with so many options. You worry about making the wrong choice or ‘greenwashing’. Focus on materials, smart design, and the machines that make it possible.

Select materials like recycled paperboard or FSC-certified sources. Design packaging that’s right-sized and minimalist. Crucially, ensure your machinery can efficiently process these materials and designs with minimal waste.

Dive Deeper: Making Informed Sustainable Packaging Choices

Choosing truly sustainable packaging goes beyond just picking a ‘green’ material. It involves looking at the whole picture: where materials come from, how the package is designed, and how efficiently it’s made. As someone who works closely with companies in the graphic arts and paper converting industries, I see this challenge daily. The right equipment empowers you to make better choices.

Understanding Material Choices

The foundation of sustainable packaging is the material. You have several options, each with pros and cons. Recycled paperboard is great because it uses post-consumer waste. Virgin fibers might be needed for strength, but look for certifications like FSC (Forest Stewardship Council) which ensure responsible sourcing. Biodegradable or compostable options exist, but their end-of-life needs careful consideration – do your customers have access to industrial composting?

| Material Type | Pros | Cons | Best Use Case (with right equipment) |

|---|---|---|---|

| Recycled Paperboard | Uses waste, lower footprint | Can have strength/print limitations | General boxes, inserts |

| FSC-Certified Virgin | Responsibly sourced, strong, prints well | Higher initial footprint than recycled | High-end rigid boxes, demanding uses |

| Biodegradable | Breaks down under specific conditions | May not break down in landfill, infrastructure needed | Niche applications, food service |

Modern machinery, like the systems we provide at Kylin Machine, is designed to handle these varied materials smoothly, ensuring good results even with recycled content.

The Role of Design in Sustainability

Less is often more. "Right-sizing" means designing packaging that fits the product perfectly, avoiding unnecessary filler material and reducing overall volume. "Lightweighting" involves using the minimum material thickness needed for protection. Both strategies cut down material use, reduce weight for shipping, and ultimately lower costs and environmental impact. Good design also considers the end-of-life – can the consumer easily separate components for recycling? Can the box be flattened easily?

How Equipment Influences Choices

This is where your machinery partner becomes vital. Can your current equipment handle thinner, recycled materials without jamming or causing defects? Can it produce complex, material-saving designs accurately? Advanced machines offer the precision needed to work with sustainable options effectively. For example, our Robotic Spotter systems ensure perfect placement, reducing waste from misaligned components, which is especially important when using premium, eco-friendly materials. The ability to quickly change formats also means you can produce right-sized boxes for various products without excessive downtime or material waste during setup.

How can you make packaging more sustainable?

Your current packaging process feels wasteful. You face pressure to improve, but aren’t sure where to start. Specific actions, powered by efficient machinery, make sustainability practical and achievable.

Make packaging more sustainable by optimizing material use with precision equipment, reducing energy consumption per box, minimizing production waste through accuracy, and choosing versatile machinery adaptable to eco-friendly designs.

Dive Deeper: Practical Steps Towards Sustainable Production

Making your packaging operations greener isn’t just a single decision; it’s a continuous process of improvement. I’ve worked with many businesses, from small workshops to large groups, helping them integrate more sustainable practices. The key is often upgrading or optimizing their machinery, as this unlocks significant gains in material efficiency, energy use, and waste reduction. Let’s look at some concrete ways your equipment helps you achieve this.

Optimizing Material Usage

Every square inch of paperboard saved counts. Older machines might require larger margins for error or produce more offcuts during die-cutting or forming. Modern equipment, especially systems with advanced controls like Kylin’s Robotic Spotters and Hybrid lines, offers incredible precision. This means you can design components to nest closer together, use board more efficiently, and minimize the trim waste generated. Features like precise gluing systems also ensure strong bonds with less adhesive, further reducing material consumption. This accuracy allows confidence in using slightly thinner, lighter materials where appropriate, directly contributing to lightweighting goals.

Energy Efficiency in Production

Manufacturing consumes energy, but the amount varies hugely between machines. Newer box-making equipment is designed with energy efficiency in mind. Motors are more efficient (using Variable Frequency Drives – VFDs), heating elements for glue systems are better controlled, and mechanisms are optimized for lower friction and power draw. Faster setup times and automated changeovers, common on advanced machinery, also mean the machine spends less time idling and more time producing efficiently.

| Feature Comparison | Older Machine (Conceptual) | Modern Kylin Machine (Conceptual) | Sustainability Impact |

|---|---|---|---|

| Energy per 1000 Boxes | 15 kWh | 10 kWh | Lower operational carbon footprint |

| Setup Time | 60 mins | 15 mins | Less idle energy consumption |

| Drive System | Standard Motor | High-Efficiency Motor with VFD | Reduced peak and overall power usage |

| Waste Rate | 3-5% | <1% | Less energy wasted on rejected products |

Waste Reduction Strategies

Waste isn’t just about excess material; it’s also about rejected products. Poorly formed boxes, inaccurate gluing, or misaligned wraps all lead to costly waste. High-precision machinery significantly reduces these issues. Consistent quality means fewer rejects. Some modern systems incorporate inline quality checks, automatically identifying and potentially ejecting faulty items early in the process, preventing further resources from being wasted on them. Furthermore, having versatile machines that can handle various box types (rigid, collapsible, round) means you might need fewer separate lines, simplifying operations and reducing the potential points for waste generation across your factory floor.

How does the right equipment help choose sustainable packaging for specific products?

Matching sustainable packaging to each unique product feels tricky. You risk under-protecting items or using excessive, wasteful packaging. Flexible equipment enables tailored, effective, and eco-friendly solutions.

The right equipment provides the versatility to create precisely sized, protective, and sustainable packaging (like rigid or collapsible boxes) tailored to specific products, efficiently using eco-friendly materials.

Dive Deeper: Tailoring Sustainable Packaging with Equipment

One size rarely fits all, especially in packaging. Your products – whether electronics, cosmetics, books, or food items – have unique protection requirements. The challenge is meeting these needs sustainably. From my base here in Dongguan, serving clients worldwide, I’ve seen how crucial adaptable machinery is. You need equipment that lets you create the right sustainable package for each product, not just a generic eco-box.

Balancing Protection and Material Use

Sustainable doesn’t mean flimsy. Often, products require robust protection. This is where structures like rigid boxes excel. Modern equipment, like the Kylin lines specializing in rigid box making, can create incredibly strong, high-quality boxes using surprisingly minimal material, thanks to precision forming and gluing. You can achieve premium protection using recycled or FSC-certified boards. For items needing less rigidity but benefiting from shipping efficiency, machines capable of producing collapsible boxes allow for sturdy designs that ship flat, saving space and resources. The key is having machinery that can accurately and efficiently produce these specific structures using sustainable materials.

Versatility for Different Product Needs

Your product line likely isn’t static. You need packaging equipment that can adapt. Can your machine handle different board thicknesses? Can it switch between producing small cosmetic boxes and larger electronics packages quickly? Can it accurately place custom-designed inserts made from recycled pulp or corrugated board? Versatility is paramount. For instance, our equipment is designed to handle a wide range of sizes and formats, incorporating features like robotic arms for precise placement of components, regardless of complexity. This allows our clients in the paper converting and graphic arts sectors to offer tailored sustainable solutions to their diverse customer base.

| Product Type | Recommended Sustainable Box Style | Key Kylin Machine Feature Enabling It | Sustainability Benefit |

|---|---|---|---|

| Luxury Cosmetics | Premium Rigid Box (Recycled Board) | High-Precision Gluing, Robotic Spotting | Premium feel with reduced material impact |

| Electronics | Rigid Box w/ Pulp Insert | Accurate Insert Placement, Format Versatility | Protection, avoids plastic foam |

| Apparel | Collapsible Box (FSC Board) | Precise Folding/Gluing, Auto Setup | Reduced shipping volume, easy recycling |

| Books | Hard Book Cover (Recycled Board) | Edge Folding Accuracy, Cover Wrapping | Durability using sustainable materials |

Considering the Entire Lifecycle

Smart sustainable packaging considers what happens after the consumer receives it. Equipment that produces easily collapsible boxes encourages flattening for recycling. Designs created with clean lines and minimal mixed materials (thanks to precise manufacturing) are easier for recycling centers to process. By choosing equipment capable of producing these user-friendly and recycler-friendly designs, you extend the sustainability benefits beyond your factory doors.

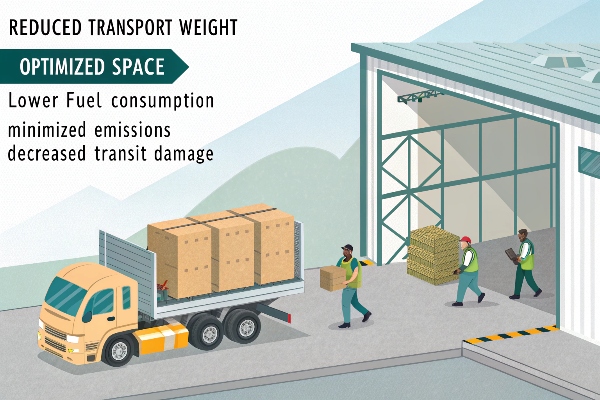

How does equipment-enabled sustainable packaging improve transportation?

Shipping costs are rising, and transport emissions are a major concern. Bulky packaging adds to the problem. Smart, efficiently made packaging significantly cuts your transport footprint.

Efficient equipment creates lightweight, dimensionally accurate, and potentially collapsible sustainable packaging. This reduces transport weight, optimizes space, lowers fuel consumption, minimizes emissions, and decreases transit damage.

Dive Deeper: Sustainable Packaging’s Impact on Logistics

Transportation is a huge part of packaging’s overall environmental impact. Every gram of weight and cubic centimeter of space saved on a truck or container translates into lower fuel consumption and reduced emissions. As a machinery manufacturer, we see how the boxes produced on our equipment directly influence logistics efficiency for our B2B clients and their customers. Investing in machinery that enables smarter packaging design is an investment in greener transportation.

Lightweighting and Material Reduction

We touched on this earlier, but it’s crucial for transport. Precision machinery allows you to confidently use the thinnest possible material that still provides adequate protection. Even a small percentage reduction in the weight of each individual box adds up significantly over thousands or millions of units shipped. Lighter packages mean less fuel is needed to transport the same number of products. Machines that handle materials consistently ensure that lightweighting doesn’t compromise the box’s structural integrity during the bumps and stresses of transit.

Optimizing Space and Volume

Space on a pallet, in a container, or on a truck is valuable. Boxes produced with high dimensional accuracy stack more efficiently, maximizing the use of available space and potentially fitting more products into a single shipment. This is where features like precise 90-degree corner forming on rigid box machines become important. Furthermore, the ability to produce collapsible boxes offers a massive advantage. These boxes ship flat to the point of packing and can often be easily flattened by the end consumer for return logistics or recycling, drastically reducing volume.

| Packaging Type | Transport Benefit | Enabling Kylin Machine Feature | Logistics Impact Example |

|---|---|---|---|

| Lightweight Rigid Box | Reduced weight per unit | Precision material handling | Lower fuel consumption per shipment |

| Accurate Rigid Box | Improved stacking density | Accurate forming/gluing | More units per pallet/truck, fewer trips needed |

| Collapsible Box | Reduced volume (shipped flat/return) | Precise folding/gluing mechanisms | Lower cost/emissions for empty box transit/storage |

| Right-Sized Box | Less void fill needed, smaller cube | Format flexibility, quick changeover | Reduced dimensional weight charges, better space utilization |

Durability and Reduced Damage

Sustainable packaging must still protect the product. Damage during transit is incredibly wasteful – it requires replacements, reverse logistics (shipping items back), and disposal of the damaged goods and packaging. Well-constructed boxes, made on reliable equipment like Kylin’s, provide the necessary durability. Strong, accurately applied glue seams and precisely formed corners ensure the box holds up during shipping. By minimizing damage, efficient machinery indirectly reduces the environmental impact associated with replacements and returns, making the entire supply chain more sustainable.

Conclusion

Choosing the right box-making equipment, like the advanced solutions from Kylin Machine, is fundamental to achieving your sustainable packaging goals, enhancing efficiency, and reducing waste throughout the process.

About Me:

My name is Jacob, and I represent Kylin Machine (www.kylinmachines.com) from Dongguan, China. We specialize in high-tech machinery like Robotic Spotters and Hybrid systems for rigid box and hard book cover production, serving the graphic arts, paper converting, and bookbindery industries worldwide on a B2B wholesale basis since 2003.

发表回复