How Is Book Edge Gilding Done?

Are your book edges looking a bit plain? It feels like you’re missing that special touch that customers notice. Edge gilding adds instant elegance and value to your products.

Edge gilding means applying a thin layer of metallic foil, usually gold-colored, to the edges of a book block. It makes books look luxurious and helps protect the pages from dust and moisture. The basic process involves preparing the edge, applying the foil, and finishing.

It sounds simple on the surface, but there’s actually quite a bit more to getting that perfect, shiny edge. I often get questions about the specifics from people in the printing and packaging business. Understanding these details can really help you decide if adding gilding services is the right move for your company, and how to do it effectively. Let’s break down some of the common questions I hear.

How Do You Actually Gilt an Edge?

Trying to gilt edges perfectly by hand can be really difficult and time-consuming. You might worry about getting it uneven or wasting expensive foil materials. Using a specialized machine makes the whole process much smoother and more consistent.

To gilt an edge properly, you first need a perfectly smooth surface, usually created by sanding or polishing. Then, you typically apply heat to activate the foil’s adhesive layer, or use a separate adhesive. You press the foil onto the edge firmly and then peel away the excess carrier film.

Based on my experience at Kylin Machine, helping businesses implement this process, manual methods often lead to inconsistencies. Our machines are designed to simplify and perfect these steps. First, the book block (the stack of pages) is clamped very tightly to keep the pages aligned. Then, an integrated sanding or polishing unit works on the edge to make it perfectly flat and smooth. A key feature we’ve included in models like our KY-530A book edge gilding machine and KY-210 is a high-power dust suction system 12. This immediately collects the paper dust created during sanding. This is crucial – it keeps the working area clean, which is better for the environment and absolutely essential for getting the foil to stick properly without bumps or defects.

After preparation, the foil is applied. Our machines use precisely controlled heat and pressure. These settings are adjustable, which is important because different types of foil materials require different conditions for optimal results 12. The foil feeder system is also designed to advance the foil efficiently, minimizing waste and saving you money on materials 12. Some of our machines can even handle gilding on round corners, adding another level of sophistication you can offer 12. Automating these steps ensures a consistent, high-quality finish every time, something that’s very hard to achieve manually.

| Feature | Manual Gilding | Machine Gilding (e.g., Kylin) | Benefit of Machine |

|---|---|---|---|

| Clamping | Manual press or clamps | Automatic, high-pressure clamping | Consistency, prevents shifting |

| Smoothing | Hand sanding/polishing | Integrated sanding/polishing unit | Speed, uniform surface |

| Dust Removal | Manual wiping/brushing | Integrated high-power suction 12 | Cleanliness, better adhesion |

| Foil Apply | Hand pressure, basic heat tool | Controlled heat & pressure 12 | Even application, fewer flaws |

| Foil Feed | Manual cutting & placement | Automated feeder, low waste 12 | Material cost savings |

| Consistency | Varies greatly by skill | High, repeatable results | Reliable quality output |

| Speed | Slow | Much faster | Increased productivity |

Using a dedicated machine like those we offer at Kylin Machine 34 transforms edge gilding from a difficult craft into a reliable production process.

Why Are Book Edges Gilded Anyway?

Do plain book edges sometimes make your products look a little ordinary? You might see competitors offering books with that extra visual appeal. Gilding is a straightforward way to instantly elevate the perceived value and look of a book.

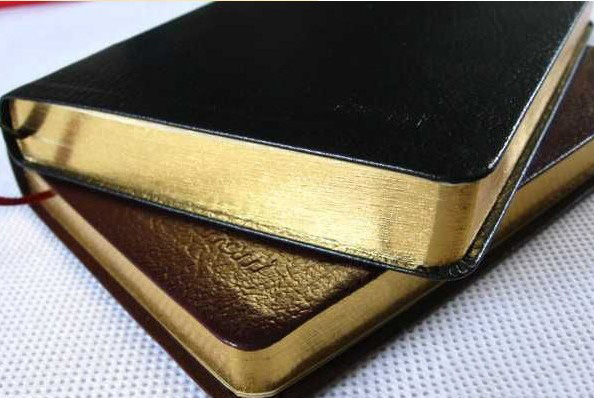

Book edges are gilded mainly for aesthetics – it adds a touch of luxury, expense, and visual interest. It also offers some protection by sealing the paper edges against dust and moisture. Historically, it was a hallmark of high-quality or important books, like Bibles 45.

Let’s look closer at why this matters to businesses like yours, the ones we serve in the graphic arts, paper converting, and bookbindery industries.

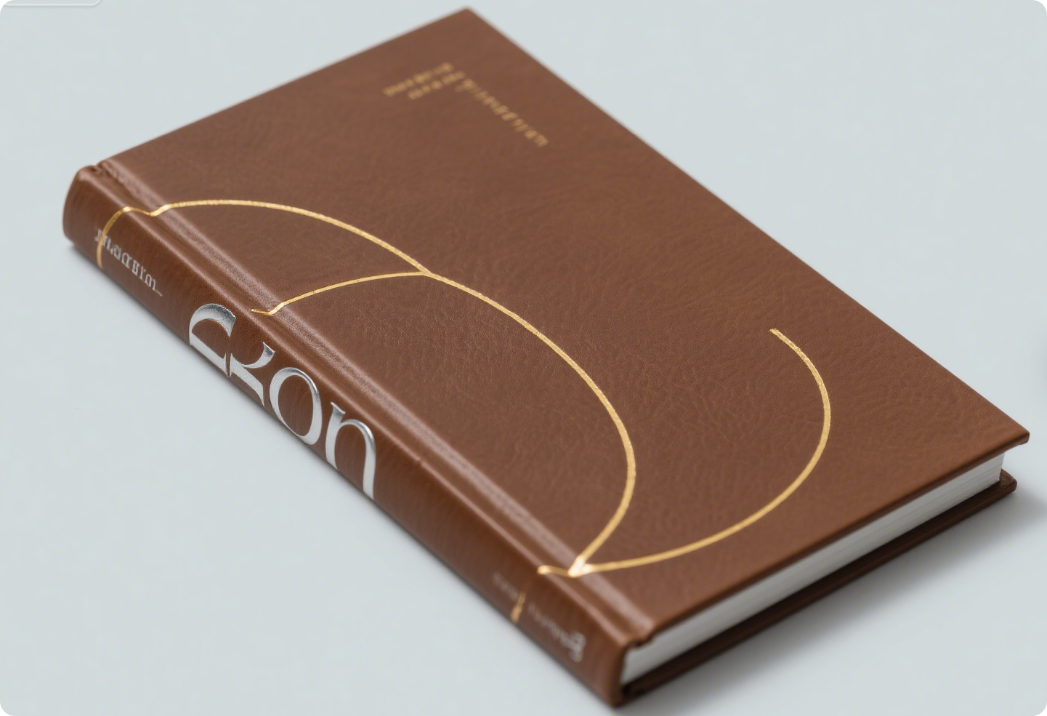

First and foremost is aesthetics. A shiny, metallic edge just looks premium. Think about high-end notebooks, special edition fiction, religious texts, photo albums, or corporate annual reports. A gilded edge makes the item feel more special and valuable. It helps your product stand out on a shelf or feel more substantial as a gift. This visual appeal can be a key differentiator.

Second is protection. While it won’t make a book waterproof, the layer of foil does seal the edges of the paper block. This helps reduce the amount of dust that can settle between the pages over time. It also offers a slight barrier against humidity and moisture absorption through the edges, which can help the book last longer and stay looking good. This adds to the perception of quality.

Third is tradition and perceived value. For centuries, especially before modern mass production, gilding was a sign of a well-crafted, important, or expensive book. Using gilt edges today connects to that history. It signals to the buyer that this isn’t just an ordinary book; it’s something more special.

For printing and packaging businesses, offering edge gilding allows you to provide a value-added service. You can charge a premium for products with gilt edges, increasing your profit margins. It’s a way to meet customer demands for more luxurious or differentiated products. Our machines at Kylin Machine, ranging from semi-automatic models perfect for smaller runs 12 to fully automatic lines for high volume 36, are designed to make adding this capability efficient and cost-effective.

| Reason for Gilding | Description | Business Benefit |

|---|---|---|

| Aesthetics | Creates a luxurious, premium, eye-catching look. | Differentiation, justifies higher price point. |

| Protection | Seals edges against dust, some moisture resistance. | Increased product longevity, perception of quality. |

| Tradition | Connects to historical bookbinding practices. | Signals importance, adds perceived value. |

| Value-Add | Enhances basic product into a premium offering. | Opportunity for increased profit margins. |

Adding edge gilding capabilities can be a smart move to enhance your product offerings and appeal to clients looking for that extra touch of quality.

What Is That Gold Edging on a Book Called?

Have you ever wondered what the proper term is for that shiny gold or metallic edge you see on some books? Using the wrong term when discussing projects or ordering supplies can sometimes lead to confusion. Knowing the right name helps communication within the industry.

The correct technical term for the metallic finish applied to the edges of a book block is "gilt edges" or simply "edge gilding." While people might say "gold edges" if the color is gold, "gilt" is the general term that covers any metallic foil applied this way.

So, the process itself is called edge gilding, and the result you see on the book is referred to as gilt edges. The word "gilding" historically means applying a thin layer of gold or a gold-like substance to a surface. While traditional bookbinding might have used real gold leaf (which is very expensive!), modern edge gilding almost always uses hot stamping foils.

These foils consist of a carrier layer, a release layer, a lacquer layer (which provides the color or metallic sheen), and an adhesive layer activated by heat and pressure. They come in a huge variety of finishes – not just classic gold, but also silver, copper, bronze, various metallic colors, and even holographic or patterned effects. Our Kylin edge gilding machines are built to handle these different types of foil materials effectively, thanks to features like adjustable temperature and pressure controls 12. This flexibility allows you to offer a wide range of decorative options to your clients.

It’s also useful to know that edge gilding is different from other edge treatments. For example, fore-edge painting is where an artist paints a miniature scene on the edges of the pages, often visible only when the pages are fanned. Marbled edges involve transferring a swirling pattern onto the edges, similar to marbled paper. Knowing the specific term "edge gilding" helps ensure clarity when you’re discussing job specifications, ordering foil supplies, or talking about machine capabilities like those offered by Kylin Machine 4. It makes conversations more precise and professional.

How Do You Prepare and Dust Book Edges?

Is dust or an uneven surface ruining your edge gilding results? It’s frustrating when a poorly prepared edge leads to wasted foil, lost time, and subpar products. Proper preparation is absolutely the most critical step for achieving a perfect, mirror-like gilt finish.

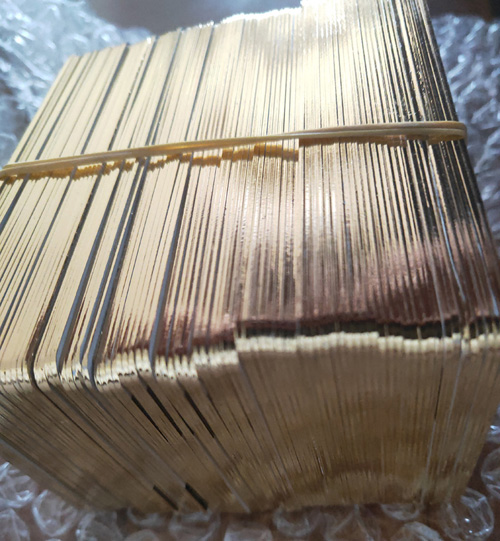

Before any gilding foil is applied, the book edges must be perfectly smooth, clean, and held tightly together in a clamp or press. This usually involves sanding or polishing the edge surface. Critically, all resulting paper dust must be removed completely for the foil to adhere properly.

In my experience helping customers set up their gilding operations, I’d say preparation accounts for maybe 80% of the final quality. If the prep isn’t right, the gilding won’t be right.

First, the book block (the stack of pages without the cover) needs to be clamped very securely. A hydraulic press or strong pneumatic clamp is often used. The pressure needs to be high enough to make the edge solid, preventing any page movement and ensuring a perfectly flat surface. If pages shift, the edge won’t be smooth.

Next comes smoothing the edge. This typically involves sanding or sometimes polishing. The goal is to get the edge incredibly smooth, almost like glass. Any imperfections, ridges from the paper, or unevenness will show through the thin foil layer, spoiling the effect.

But the step that often causes problems if not done right is dust removal. Sanding paper creates fine dust. Even tiny specks left on the edge will interfere with the foil’s adhesive, causing bumps, pits, or areas where the foil doesn’t stick at all. This was a major pain point we specifically addressed when designing our Kylin edge gilding machines 12. Models like the KY-530A and KY-210 integrate the sanding/polishing unit directly with a powerful wind suction system 12. As the edge is being smoothed, the dust is immediately vacuumed away. This has multiple benefits:

- It keeps the work area much cleaner (100% Environment protection noted in specs 12).

- It’s better for the operator’s health.

- Most importantly for quality, it ensures a pristine surface ready for the foil application.

This integrated approach saves a separate, often tedious and imperfect, manual cleaning step. It directly improves the consistency and quality of the final gilt edge, leading to fewer rejects and less wasted material – addressing key pain points around quality control and cost for our customers.

Conclusion

Edge gilding is a fantastic way to add significant value, aesthetic appeal, and a touch of protection to books and notebooks. The process hinges on careful preparation, especially smoothing and dust removal, followed by precise foil application using heat and pressure. While possible manually, modern automated machines like those from Kylin Machine 3 make edge gilding efficient, consistent, and a viable service offering for printing and packaging businesses looking to enhance their products.

-

Detail of Ky-530A gilding machine.pdf (https://kylinmachines.com/Machine/book-edge-gilding-machine/) ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Detail of Ky-210 gilding machine.pdf (https://kylinmachines.com/Machine/business-card-edge-gilding-machine/) ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Detail of fully auto book edge gilding machine.pdf (https://postpressmachines.com/Machine/fully-auto-book-edge-gilding-machines/ ↩ ↩ ↩

-

https://iboxmachine.com (Product listings include Bible book edge gilding machine) ↩ ↩ ↩

-

https://iboxmachine.com (Product listings show various book-related machines, implying target market familiarity) ↩

-

Detail of fully auto book edge gilding machine.pdf (https://postpressmachines.com/Machine/fully-auto-book-edge-gilding-machines/) ↩

发表回复