How to choose the best book binder for your needs?

Choosing the right book binder feels complicated. Making the wrong choice wastes time and money, hurting your production. Understanding the key factors helps you pick the perfect machine.

Selecting the best book binder means matching your specific needs (like book type, production volume, and quality goals) with the machine’s capabilities. Key factors include durability, binding speed, ease of use, and the type of binding it performs.

Choosing binding equipment is a big decision for any printing or packaging business. It impacts your workflow, product quality, and ultimately, your bottom line. As someone who’s been in the post-press machinery business with Kylin Machine since 2003, I’ve seen firsthand how crucial the right binder is. Let’s break down the common questions to help you navigate this choice. We need to look closer at the different types and methods available.

Which type of binding is best for books?

You see so many binding types available. It’s confusing knowing which one fits your specific books and budget best. Let’s compare the most common methods simply.

There isn’t one single "best" type of binding. The ideal choice depends entirely on the book’s purpose, how long it needs to last, the number of pages, and your budget. Common types include perfect binding, case binding, and saddle stitching.

s](https://kylinmachines.com/wp-content/uploads/2025/04/book-binder1.jpg)

Choosing the binding type really sets the stage for the final product. It affects the look, feel, durability, and cost. Let’s dive deeper into the main options many businesses consider.

Perfect Binding

This is very common for paperbacks, journals, and thicker magazines. Pages are stacked, the spine edge is milled (roughed up), strong glue is applied, and then the cover is wrapped around. It gives a clean, flat spine where you can print text. It’s quite cost-effective for medium to high volumes. The machine process involves collating signatures, milling the spine, applying hot-melt glue (like EVA or the stronger PUR), and then pressing the cover firmly onto the glued spine.

Case Binding (Hardcover)

This is the gold standard for durability and perceived quality, used for hardcover books, yearbooks, and high-end products. The inside pages (book block) are often sewn together, then glued to endpapers, which are then glued to stiff cover boards. This method creates a very durable book that can last for generations. At Kylin Machine, we specialize in machinery for this type of high-quality binding, focusing on creating robust hard book covers efficiently, often using advanced robotic systems for precision.

Saddle Stitching

Think of thin booklets, magazines, or brochures. Pages are folded, nested inside each other, and then stapled or stitched through the fold line with wire staples. It’s simple and very inexpensive for low page counts (usually under 64-80 pages, depending on paper thickness). Books lay relatively flat, but it’s not very durable for heavy use.

Here’s a simple comparison:

| Feature | Perfect Binding | Case Binding (Hardcover) | Saddle Stitching |

|---|---|---|---|

| Durability | Moderate to Good | Excellent | Low |

| Cost | Medium | High | Low |

| Appearance | Professional, Flat Spine | Premium, Durable | Simple, Booklet |

| Page Count | Medium to High | High | Low |

| Lay-flat? | No (Generally) | Fair to Good (Sewn) | Yes |

| Typical Use | Paperbacks, Journals | Hardcover Books, Albums | Booklets, Mags |

Understanding these types helps narrow down what kind of machine you might need.

What is the best book binding method?

You know the types now, but which method or process is truly superior? Choosing incorrectly impacts your final product quality and how efficiently you can produce it. Think about your specific production goals.

Again, the "best" method is subjective. It truly depends on what you value most: top quality, high production speed, lowest cost per unit, or the book’s specific job. Case binding offers peak quality, while perfect binding balances cost and volume effectively.

The "method" involves not just the binding type but also how it’s done – particularly the level of automation and the quality of the machinery involved. This is where efficiency and consistency really come into play.

Factors Defining the "Best" Method for You

What does "best" mean in your context?

- Quality: Do you need archival-quality books or just functional short-term use items? Case binding usually means higher quality.

- Volume: Are you binding hundreds or thousands of books per day? High volume demands automated solutions like those we build at Kylin Machine.

- Budget: What’s your initial investment capacity versus long-term running cost tolerance? Manual methods have low entry costs but high labor costs per unit.

- Book Type: The book’s purpose (e.g., textbook vs. novel vs. manual) heavily influences the method.

Manual vs. Automated Binding

Manual binding involves significant hands-on work for folding, gluing, pressing, etc. It’s suitable for very small runs or bespoke projects but is slow and consistency can vary. Automated binding uses machinery to handle most or all steps. This dramatically increases speed, ensures consistency, and reduces labor cost per book, though the initial machine investment is higher.

| Aspect | Manual Binding | Automated Binding |

|---|---|---|

| Speed | Very Slow | Fast to Very Fast |

| Consistency | Variable | High |

| Initial Cost | Low | High |

| Labor Cost/Unit | High | Low |

| Skill Required | High (for quality) | Moderate (for operation) |

| Volume Suitability | Very Low | Medium to High |

The Role of Machinery Quality

The best method often requires the best machine for that method. A cheap perfect binder might cause issues with glue application or cover alignment, leading to books falling apart. A high-quality case binding machine, like the ones we design at Kylin Machine with advanced features, ensures precision, durability, and efficient production of premium hardcover books. Investing in reliable machinery is key to making your chosen binding method truly "best" in practice.

What is the best material to bind a book?

The materials you choose directly impact the book’s final look, feel, and lifespan. Using unsuitable materials can lead to a poor-quality product or cost you more than necessary. Understand the options.

The "best" material depends on the binding method and the desired result. Key materials include glues (like EVA or PUR) for perfect binding, thread for sewn sections, and various cover boards, cloths, and papers for case binding.

Materials are the building blocks of the bound book. Choosing wisely is just as important as selecting the right binding method or machine. Let’s look at the common ones.

Adhesives: The Backbone of Perfect Binding

For perfect binding, the glue is critical.

- EVA (Ethylene Vinyl Acetate): This is a common hot-melt adhesive. It’s cost-effective and easy to use but can become brittle over time or in extreme temperatures. It works well for short-term use books or those not expected to endure heavy handling.

- PUR (Polyurethane Reactive): This is also a hot-melt adhesive, but it reacts with moisture in the air (or paper) to cure, forming a much stronger, more flexible bond than EVA. It’s excellent for durability, works well on coated papers, and withstands temperature variations better. It costs more and requires specific handling, but the quality difference is significant. Machines need to be compatible with the type of glue used.

Covers: Defining Hardcover and Softcover

- Softcover: Typically uses heavier weight paper or cardstock (e.g., 250-350 gsm), often coated or laminated for durability and visual appeal. Used in perfect binding, saddle stitching etc.

- Hardcover (Case Binding): Requires rigid boards (greyboard or chipboard) of varying thickness. These boards are then covered with materials like:

- Cloth: Durable, traditional, comes in various textures and colors.

- Paper: Can be printed with complex graphics, often laminated for protection.

- Leather/Faux Leather: Premium options for high-end books.

The choice affects cost, durability, and aesthetics. Our Kylin machines are built to handle the demanding process of precisely applying covers to boards for high-quality case making.

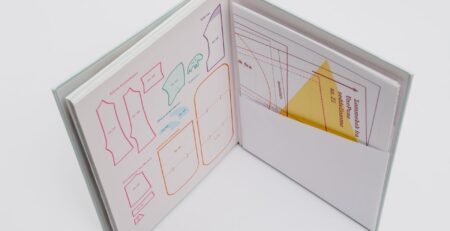

Reinforcement Materials

Especially in case binding, other materials add strength:

- Thread: Used for sewing book sections (signatures) together before casing-in. Creates a very strong, flexible book block that can lay flatter.

- Endpapers: Strong sheets of paper glued to the inside of the front and back covers and the first/last pages of the book block. They hold the book block inside the cover.

- Mull or Crash: A gauze-like cloth glued onto the spine of the book block before casing-in to add strength and reinforcement.

The best materials work together with the binding method and the machinery’s capabilities to produce the desired final book.

What is perfect book binding?

You’ve likely heard the term "perfect binding" often. But what does it actually mean for a book? Not understanding it might lead you to choose it when another method is better suited. Let’s define it clearly.

Perfect binding is a popular method where book pages are stacked, the spine edge is roughed up, strong adhesive is applied, and a wrap-around cover creates a flat, printable spine. It’s widely used for paperbacks, magazines, and corporate reports.

Perfect binding is one of the most common methods you’ll encounter, especially for commercially produced softcover books. It offers a good balance between cost and a professional appearance. Let’s break down how it works and its pros and cons.

The Perfect Binding Process Step-by-Step

- Collation: Printed pages or folded sections (signatures) are gathered in the correct order to form the book block.

- Milling/Roughing: The spine edge of the stacked book block is ground off or roughed up. This creates a larger surface area with exposed paper fibers for the glue to adhere to effectively. Notching (cutting small grooves) might also be done.

- Glue Application: Hot melt adhesive (usually EVA or PUR) is applied evenly along the roughed spine edge. The amount and temperature are crucial.

- Cover Application: The pre-scored cover is fed into position and wrapped tightly around the book block, adhering to the glued spine.

- Nipping/Pressing: The book is pressed firmly, especially at the spine, to ensure a strong bond between the book block and the cover as the glue sets.

- Trimming: Finally, the three open sides of the book (top, bottom, face) are trimmed to create smooth, perfectly aligned edges.

Advantages of Perfect Binding

- Professional Look: Creates a clean, square spine suitable for printing titles.

- Cost-Effective: Generally less expensive than case binding, especially at higher volumes.

- Versatile: Works for a wide range of page counts (typically from 40 to 400 pages, depending on paper).

Limitations of Perfect Binding

- Doesn’t Lay Flat: Books don’t naturally stay open easily, requiring them to be held open.

- Durability Varies: Lifespan depends heavily on the glue quality (PUR is much better than EVA), paper type, and usage. Spines can crack over time.

- Not Ideal for Very Thick/Heavy Books: Stress on the spine can be too great.

While perfect binding is excellent for many applications, it doesn’t offer the supreme durability or lay-flat qualities often found in sewn case binding, which is an area Kylin Machine focuses on providing high-tech solutions for. Understanding perfect binding helps you appreciate when case binding is the better, more durable choice.

Conclusion

Choosing the right book binder comes down to matching your needs—book type, volume, quality—with the right method, materials, and reliable machinery. Consider partners like Kylin Machine for robust hardcover solutions.

Jacob

www.kylinmachines.com

Kylin Machine

发表回复