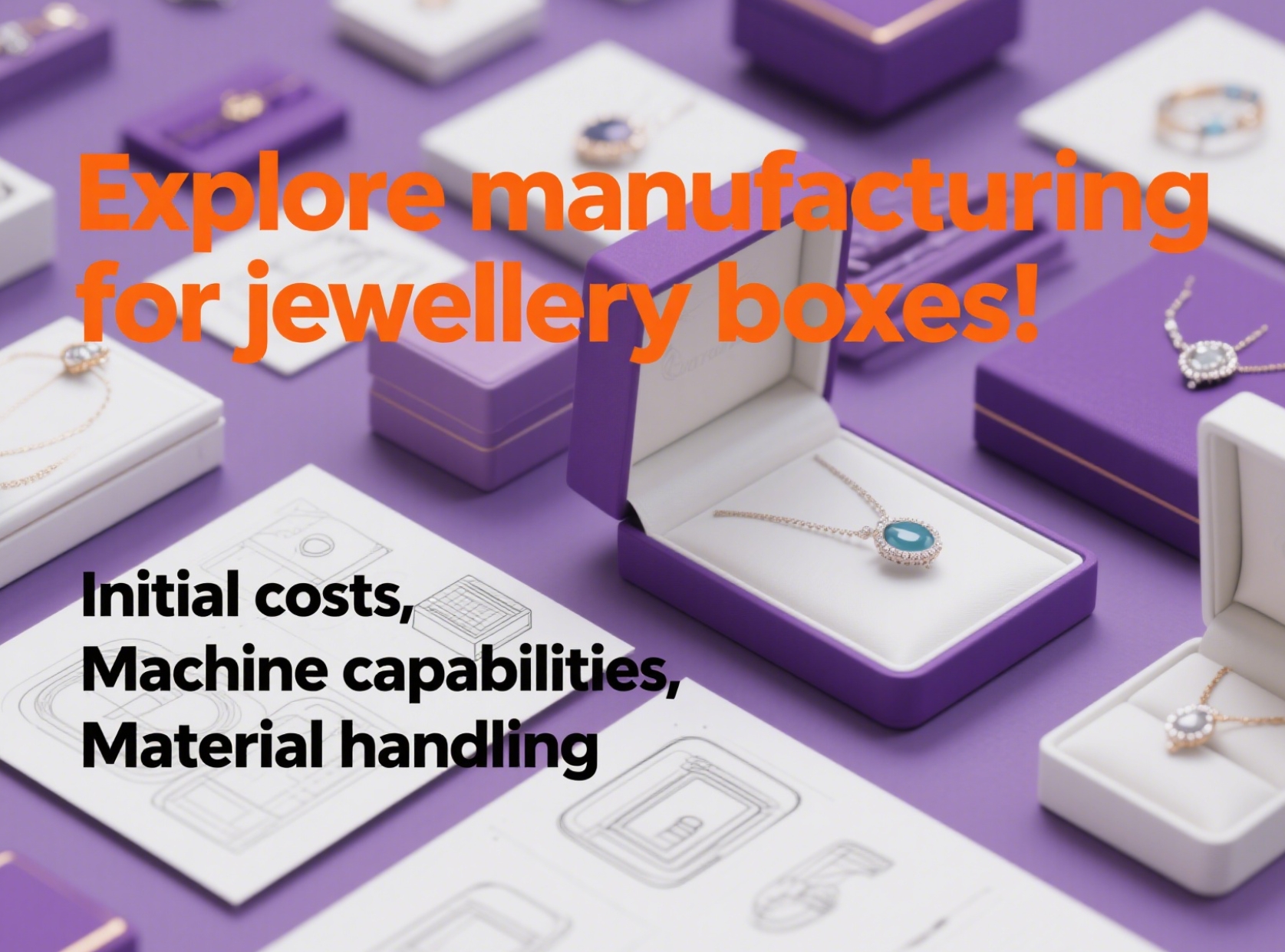

Stepping into Jewellery Box Manufacturing: What Do You Need to Know?

Struggling with slow, handmade packaging? Customer demands are rising, and keeping up is tough. It’s time to explore manufacturing for speed and quality.

Yes, you can transition from trading to manufacturing jewellery boxes. Understanding initial costs, machine capabilities, and material handling is key. This guide breaks it down for you.

Moving from sourcing to creating your own packaging line might seem daunting. But with the right information and a clear plan, it’s a journey that can transform your business. Let’s explore the specifics to help you make informed decisions and set you on the path to success.

What’s the Initial Investment and What Types of Boxes Can I Make?

Worried about startup costs? Unsure what machines can produce? Initial investment can be a hurdle, but clarity on capabilities makes it manageable.

Initial investment varies, but entry-level machines for rigid boxes can be a starting point. With Kylin Machine solutions, you can produce various high-quality jewellery boxes.

Starting your own jewellery box manufacturing line involves several cost factors. As Jacob from Kylin Machine, with over two decades in post-press machinery, I’ve seen many businesses like yours make this leap.

Key Investment Areas:

- Machinery: This is often the largest initial outlay.

- Entry-Level: For basic jewelry box making, you might look at semi-automatic jewlery box machines. These offer a good balance between investment and output for newcomers.

- Advanced Solutions: As you grow, fully automatic jewelry box lines like our Kylin Machinery series can significantly boost production for various box types, including those complex designs popular in the jewellery sector.

- Space: You’ll need a dedicated area for machinery, material storage, and assembly. Our factory in Dongguan is 5,000 square meters, but you can start smaller and scale.

- Manpower: Skilled operators are crucial. While our machines are designed for ease of use, initial training is important.

- Raw Materials: Budget for initial stock of paperboard, glues, and covering materials.

Types of Boxes You Can Make:

With the right equipment, the possibilities are extensive. Kylin Machine specializes in machinery for:

- jewelry Boxes: The classic, sturdy jewellery box. Our machines handle various sizes and complexities.

- Collapsible Boxes: Space-saving and modern, increasingly popular.

- Custom Shapes: While we have standard machines, we also offer solutions for polygonal or unique designs, which can be a great differentiator in the luxury packaging market.

Our focus on high technology, like Robotic Spotters, ensures precision for even intricate designs. We’ve helped over 2,500 users in 20+ countries set up their production.

| Machine Type | Box Types Possible | Initial Investment Range (Illustrative) |

|---|---|---|

| Semi-Auto jewlery Box machine | Basic rigid boxes, small to medium | Low to Medium |

| Fully-Auto jewlery Box machine | High volume rigid, complex designs | Medium to High |

| Speciality box Machines | Collapsible, round, polygonal boxes | Varies based on complexity |

Remember, the "right" investment depends on your target volume and box complexity. We at Kylin Machine can help you analyze your needs.

How Can I Handle Different Covering Materials Like Velvet or PU?

Diverse materials attract customers, but are they hard to work with? Wrapping with velvet, PU, or leatherette seems complex. Proper machinery simplifies this.

Our machines are designed to handle various covering materials, including delicate ones like velvet and robust ones like PU leatherette, ensuring a premium finish for your jewellery boxes.

As a trader, you’re familiar with the appeal of different outer coverings – leatherette paper, PU/rexine, velvet, satin. These materials significantly enhance the perceived value of jewellery packaging. The good news is, modern machinery is adept at handling these.

Challenges and Solutions with Various Materials:

- Velvet & Satin: These are delicate and can be prone to creasing or glue stains if not handled correctly.

- Kylin Machine Solution: Our jewlery box gluing systems and jewelry box wrapping units are designed for precise adhesive application and gentle handling. Features like adjustable pressure and temperature control on some models ensure these fabrics are applied smoothly without damage. We focus on technology that minimizes waste and maximizes quality.

- Kylin Machine Solution: Our jewlery box gluing systems and jewelry box wrapping units are designed for precise adhesive application and gentle handling. Features like adjustable pressure and temperature control on some models ensure these fabrics are applied smoothly without damage. We focus on technology that minimizes waste and maximizes quality.

- PU/Rexine & Leatherette Paper: These are more robust but require accurate cutting, creasing, and strong adhesion.

- Kylin Machine Solution: Our machines offer precise cutting and forming. For these materials, consistent glue application and strong bonding are key. Our equipment, developed through years of R&D, ensures durable and aesthetically pleasing results. We serve industries like Graphic Arts and Paper Converting, where material versatility is paramount.

Key Machine Features for Material Handling:

- Adjustable Gluing Systems: Whether it’s hot melt or cold glue, the ability to control the amount and pattern of adhesive is crucial for different material thicknesses and porosities.

- Precision Wrapping Units: For a tight, bubble-free finish, especially around corners and edges. Our Robotic Spotters and Hybrid technology play a big role here.

- Material Feed Mechanisms: Gentle yet firm handling to prevent stretching or tearing of delicate materials.

| Material Type | Common Challenges | Kylin Machine Approach |

|---|---|---|

| Velvet/Satin | Creasing, glue stains, tearing | Precise glue control, gentle handling, adjustable pressure |

| PU/Rexine | Adhesion, clean cuts, corner wrapping | Strong bonding systems, sharp cutting, precision forming |

| Leatherette Paper | Bubbling, consistent finish | Even glue application, smooth wrapping mechanisms |

My experience at Kylin Machine, serving over 10,000 users (Kylin Machinery Limited serves about 2,500 users) globally, has shown that the right machine makes all the difference. We can guide you on the best setup for the specific materials you plan to use.

What’s the Best Way to Ensure a Smooth Transition into Manufacturing?

Moving from trading to making is a big step. Worried about the learning curve and potential pitfalls? A strategic approach minimizes disruption.

A smooth transition involves careful planning, choosing the right machinery partner, and phased implementation. Kylin Machine offers support from setup to operation.

Transitioning from a trading business to manufacturing jewellery packaging is a significant but rewarding endeavor. I’m Jacob, and at Kylin Machine, we’ve guided many clients through this process since our founding in 2003. Here’s my advice for a smoother journey:

Phased Approach:

Don’t try to do everything at once.

- Start Small: Begin with a core product line, perhaps the most in-demand jewellery box type you currently trade. Master its production before expanding.

- Learn and Adapt: Your initial phase will be a learning curve. Use this time to refine processes, train staff, and understand your machinery’s capabilities.

- Gradual Expansion: Once comfortable, gradually introduce new box types or materials.

Choosing the Right Partner:

This is crucial. Look for more than just a machine supplier.

- Expertise: Your partner should understand your industry. Kylin Machine specializes in post-press and packaging machinery, particularly for rigid boxes and hard book covers – directly relevant to jewellery packaging.

- Support & Training: Ensure they offer installation, training, and after-sales service. We have a global network of distributors (Middle East, India, Turkey, etc.) and a dedicated team of over 120 workers to support our clients.

- Scalability: Choose machinery that can grow with your business. Our range includes options from semi-automatic to fully automatic lines.

Key Considerations for a Smooth Start:

| Aspect | Recommendation | How Kylin Machine Helps |

|---|---|---|

| Planning | Detailed business plan, market research, financial projections. | We can share insights on production efficiency and machine capabilities for planning. |

| Training | Invest in training for your operators. | We provide comprehensive training on machine operation and maintenance. |

| Quality Control | Implement QC processes from day one. | Our machines are built with strict QC management; we can advise on best practices. |

| Supplier Network | Establish reliable sources for raw materials. | While we don’t supply raw materials, our experience can point you to industry norms. |

My personal story involves building Kylin Machine from the ground up in Dongguan. We understand the challenges and opportunities. A smooth transition is about making informed choices and having a reliable technology partner.

Can I Make Plastic Shell Boxes Wrapped in Various Materials?

Plastic shell boxes are popular, but how are they made? Wrapping them with velvet or PU seems tricky. The right machines make this achievable.

Yes, machinery can efficiently wrap pre-formed plastic shells with materials like velvet or PU. Kylin Machine offers solutions adaptable for such applications.

You’ve noted that "mostly plastic shell boxes are used here. Wrapped with velvet, PU, leatherette paper, etc." This is a common and very popular style for jewellery packaging, offering durability from the plastic core and a luxury feel from the wrapping. As Jacob from Kylin Machine, I can confirm that this is a process our machinery can support.

Understanding the Process:

Manufacturing these boxes typically involves two main stages:

- Shell Creation: The plastic shells are usually injection molded. While Kylin Machine doesn’t manufacture injection molding machines, we focus on the crucial next step.

- Wrapping and Finishing: This is where our expertise comes in. The pre-formed plastic shells need to be accurately and beautifully wrapped with your chosen material.

How Kylin Machinery Assists:

Our rigid box making and wrapping machines can be adapted or configured for this specific application.

- Gluing Systems: Precise application of adhesive to the plastic shell or the wrapping material is key. Different adhesives might be needed for plastic compared to paperboard, and our machines offer that flexibility.

- Wrapping Units: The machines need to handle the contours of the plastic shell and ensure the material (velvet, PU, etc.) is applied smoothly, without air bubbles or creases, especially around edges and corners. Our advanced machines with robotic spotters excel at this precision.

- Material Compatibility: As discussed before, our machines are designed to work with a wide range of covering materials, ensuring a high-quality finish on the plastic core.

| Aspect of Wrapping Plastic Shells | Kylin Machine Solution Focus | Benefit for Your Business |

|---|---|---|

| Adhesion to Plastic | Compatibility with appropriate adhesives, precise application. | Durable bond, prevents peeling or material separation. |

| Conforming to Shape | Flexible wrapping mechanisms, ability to handle 3D forms. | Smooth, professional finish even on curved or complex shells. |

| Material Handling (Velvet, PU) | Gentle yet firm material feed, tension control. | Protects delicate materials, ensures consistent wrap quality. |

| Efficiency | Semi-automatic or fully automatic options for various production volumes. | Increased output compared to manual wrapping, cost savings. |

While your current suppliers might be making these by hand, mechanizing the wrapping process can significantly increase your speed and consistency, allowing you to serve more customers effectively. We at Kylin Machine have a monthly capacity of about 60 sets of packaging machines, and our R&D team is always working on solutions for evolving market needs like these.

How Do I Add Custom Printing and Hinges to My Boxes?

Customization sells, but how to add prints and hinges efficiently? Printing logos and attaching hinges seems like extra, complex steps.

Printing can be done pre- or post-production. For hinges, specialized or semi-automated solutions exist. Kylin Machine can integrate with or recommend these processes.

You’re right to focus on customization: "With printing on top lid and bottom and customer name inside top lid. Metal hinges are there." These details elevate a jewellery box from a simple container to a branded experience. I’m Jacob, and at Kylin Machine, we understand the importance of these finishing touches.

Incorporating Printing:

There are several approaches to printing on your jewellery boxes:

- Printing on Flat Sheets: The most common method is to print your designs (logos, patterns, customer names) on the covering material (paper, leatherette) before it’s wrapped onto the box structure.

- Process: This uses standard offset, digital, or screen printing. The printed sheets are then fed into our box wrapping machines.

- Kylin Machine Role: Our machines accurately position and wrap these pre-printed sheets onto the rigid box or plastic shell. Our Robotic Spotter technology is particularly beneficial for precise alignment of printed designs.

- Post-Production Printing: For some applications, like adding a small logo or text after the box is assembled, methods like hot stamping or pad printing can be used.

- Kylin Machine Role: While we specialize in box forming and wrapping, we also offer machines like hot stamping machines (e.g., our Ky-180A also has a thumb cutter). We can advise on integrating these into your workflow.

Adding Metal Hinges:

Metal hinges add a touch of class and durability.

- Manual/Semi-Automated Attachment: For smaller volumes, hinges are often attached manually or with semi-automated jigs or presses after the box is formed and wrapped.

- Specialized Machinery: For higher volumes, specialized hinge attaching machines exist.

- Kylin Machine Insight: While dedicated hinge attachment isn’t the primary focus of our core box-making lines, we are aware of these technologies. We’ve even developed solutions like our "Detail of Hinges attached machine" in the past based on client needs. We can discuss how to best integrate this step into a production line featuring Kylin machinery. Our goal is to provide comprehensive solutions, and our R&D team is capable of exploring such requirements.

| Customization Feature | Common Methods | Kylin Machine Connection |

|---|---|---|

| Printing (Lid/Base) | Offset, Digital, Screen (on flat sheets); Hot Stamping | Machines wrap pre-printed sheets accurately; Offer hot stamping machines. |

| Printing (Inside Lid) | Typically on flat liner material before insertion. | Our machines can accommodate lined boxes. |

| Metal Hinges | Manual, Semi-auto jigs, Specialized machines. | Can advise on workflow integration; have explored specialized hinge attachment solutions. |

Serving the Graphic Arts, Paper Converting, and Bookbindery industries means we’re accustomed to diverse finishing requirements. Our experience with over 2,500 users worldwide (Kylin Machinery Limited) means we’ve encountered many customisation needs and can help you find efficient solutions.

Conclusion

Transitioning to jewellery box manufacturing is achievable with careful planning and the right technology partner. Kylin Machine is here to guide you.

发表回复