What Are the Latest Automation Trends in Rigid Box Manufacturing Expected in 2025?

Struggling with slow rigid box production? Falling behind automation trends costs you business. Let’s look at the key 2025 advancements you need to know.

By 2025, expect more robotic arms for placement, AI for quality control, and IoT for real-time monitoring. These trends boost speed, precision, and efficiency, reducing waste and labor needs in rigid box manufacturing.

Knowing the trends is one thing. Choosing the right machine to leverage them is crucial for success. So, let’s dive into what makes a great machine for today’s market and beyond.

What Key Features Should You Look For in a Rigid Box Machine to Ensure High-Quality Output for Luxury Goods?

Producing flawed luxury boxes? Imperfections damage your client’s brand image and waste expensive materials. Focus on machines with features that guarantee high quality every single time.

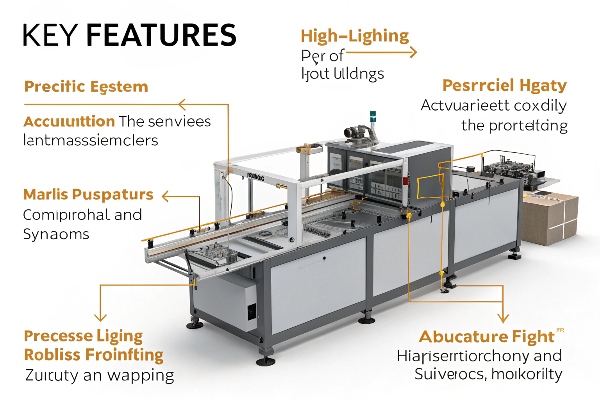

Key features are precise gluing systems, highly accurate positioning (like robotic spotters), tight and consistent wrapping, and gentle handling systems. These ensure a flawless presentation vital for luxury goods.

When producing packaging for luxury items, there’s simply no room for error. The box itself is part of the brand experience. We’ve found that focusing on specific machine capabilities is essential. At Kylin Machine, our development, especially with robotic spotters, targets these exact needs.

Uncompromising Precision

For luxury boxes, alignment must be perfect. A slightly off-center wrap or uneven glue application is immediately noticeable and unacceptable. Look for machines with advanced vision systems and, ideally, robotic spotters. These systems ensure the wrap is placed with extreme accuracy onto the glued board, consistently hitting tolerances manual methods can’t match. This level of precision minimizes rejects and upholds the premium feel.

Consistent High-Quality Output

Luxury brands demand uniformity across their entire product run. A good machine provides this through features like automated glue viscosity control, ensuring the adhesive is always optimal, and tension controls for the wrapping material. Camera-based quality inspection systems can also identify defects in real-time, preventing flawed boxes from reaching the end of the line. Consistency builds trust with your clients.

Gentle Material Handling

Luxury boxes often use delicate or textured papers. The machine must handle these materials without scuffing, scratching, or creasing. Look for features like vacuum suction systems designed for sensitive materials, smooth transfer mechanisms, and pressure controls on rollers and pressing stations. This preserves the integrity and aesthetic of the expensive materials used.

| Feature | Benefit for Luxury Goods | Why It Matters |

|---|---|---|

| Robotic Spotter | Perfect wrap-to-board alignment | Ensures flawless visual presentation |

| Vision Systems | High accuracy placement verification | Catches errors before wrapping |

| Glue Viscosity Control | Consistent adhesive application | Prevents glue seepage or weak bonds |

| Gentle Feeders | Protects delicate paper surfaces | Avoids scuffs, maintains premium look |

| QC Inspection Cams | Real-time defect detection | Reduces waste, ensures only perfect output |

How Versatile Are Modern Rigid Box Machines for Handling Different Box Types and Sizes?

Limited by machines handling only one box style or size range? Turning down diverse jobs or buying multiple machines hurts your bottom line and flexibility. Modern machines offer surprising adaptability.

Modern rigid box machines are highly versatile. Many models can handle various sizes and common styles (like standard, shoulder, collapsible boxes) with relatively quick changeovers, thanks to adjustable tooling and modular designs.

The market demands variety. One client might need small jewelry boxes, while another needs large boxes for electronics or gift sets. Having a machine that adapts is no longer a luxury; it’s often a necessity. We design our Kylin machines with this flexibility in mind, drawing on our experience since 2003.

Handling Different Box Formats

Modern machines aren’t just limited to the classic shoebox style. Many can be configured to produce neck boxes, shoulder boxes, slipcases, and even collapsible rigid boxes. This often involves interchangeable modules or tooling sets. Check the manufacturer’s specifications for the range of styles supported. Our Kylin range, for instance, includes dedicated solutions for standard rigid boxes, round boxes, and collapsible formats, reflecting this need for specialization alongside versatility within a core machine type.

Adjustability for Size Ranges

A key aspect of versatility is the range of box dimensions (length, width, height) a single machine can handle. Look for machines with easily adjustable feeders, forming stations, and pressing units. Servo motors often allow for precise, programmable adjustments, making size changes faster and more accurate than manual cranks and adjustments. The minimum and maximum size specifications are critical data points to compare.

Quick Changeover Capabilities

Versatility is only practical if changing between box sizes or types is efficient. Long downtimes for changeovers eat into profits, especially for short runs. Look for features like digital readouts, quick-release clamps for tooling, automated positioning systems (like servo adjustments), and well-organized HMI (Human-Machine Interface) controls that store recipes for different jobs. This minimizes setup time and maximizes production flexibility.

| Versatility Feature | Business Advantage | How It Works |

|---|---|---|

| Modular Tooling | Handles multiple box styles (standard, neck, etc.) | Swap specific forming/wrapping units. |

| Servo Adjustments | Wide range of sizes, fast setup | Motors precisely position guides, formers, etc. |

| Recipe Storage (HMI) | Quick recall of settings for repeat jobs | Stores parameters like size, speed, pressure. |

| Quick-Release Clamps | Faster tooling changes | Reduces manual effort and time for changeovers. |

| Wide Size Specification | Accommodates diverse customer needs | Machine structure allows large min/max dimensions. |

Is Upgrading to an Automatic Rigid Box Machine a Cost-Effective Solution Compared to Manual or Semi-Automatic Methods?

Hesitant about the upfront cost of a fully automatic rigid box machine? Sticking with slower manual or semi-automatic methods means high ongoing labor costs and limited output potential. Upgrading is often a smart long-term investment.

Yes, upgrading is frequently cost-effective. While the initial investment is higher, automatic machines significantly reduce labor costs, increase production speed, minimize material waste, and improve quality consistency, leading to a faster ROI.

The decision to upgrade involves looking beyond the initial price tag. It’s about calculating the total cost of ownership and the potential for increased revenue and profitability. We’ve seen many of our customers, from small shops to large groups across 20+ countries, successfully make this transition.

Comparing Initial Investment vs. Long-Term Savings

An automatic machine requires a significant capital outlay compared to manual setups or basic semi-auto units. However, the savings start accumulating immediately. The biggest factor is usually labor. One automatic line might replace several manual workers or significantly boost the output of a semi-auto team. Reduced waste from higher precision also cuts material costs. Increased speed means higher throughput and revenue potential from the same floor space. Over months and years, these operational savings often outweigh the initial cost difference.

Key Factors in ROI Calculation

To determine cost-effectiveness, calculate the Return on Investment (ROI). Key factors include:

- Labor Savings: Fewer operators needed per machine/line.

- Increased Throughput: Higher boxes-per-hour rate.

- Reduced Waste: Lower material costs due to fewer errors.

- Improved Quality: Fewer rejects, better client satisfaction, potentially higher pricing.

- Maintenance Costs: Compare expected upkeep for auto vs. older/manual methods.

- Energy Consumption: Modern machines can be more energy-efficient.

- Floor Space Efficiency: Higher output per square meter.

Beyond Cost: Strategic Advantages

Cost-effectiveness isn’t just about direct savings. An automatic machine provides strategic benefits. It allows you to take on larger orders, meet tighter deadlines, and compete for clients demanding high, consistent quality. It reduces reliance on finding and training skilled manual labor, which can be difficult. This enhanced capability and reliability strengthen your business’s competitive position in the graphic arts, paper converting, or bookbindery industries.

| Cost/Benefit Factor | Manual / Semi-Automatic | Fully Automatic | Impact on Cost-Effectiveness |

|---|---|---|---|

| Initial Cost | Low | High | Initial hurdle for automatic. |

| Labor Cost | High (per box) | Low (per box) | Major long-term saving for automatic. |

| Speed/Output | Low | High | Increases revenue potential. |

| Material Waste | Higher (operator dependent) | Lower (high precision) | Reduces material costs. |

| Quality Level | Variable | Consistently High | Fewer rejects, better client value. |

| Flexibility | Can be high (manual) | High (with quick changeover) | Modern auto machines are adaptable. |

| Training Needs | Requires dexterity/skill | Requires technical operation | Different skill sets needed. |

Conclusion

Automation trends push towards robotics and AI for efficiency. Choosing versatile, precise machines like those from Kylin Machine is vital for quality. Upgrading often proves cost-effective, boosting long-term profitability and competitiveness.

发表回复