What Exactly is a Tape Application Machine for Packaging?

Are you finding manual taping slow and inconsistent? These mistakes can cost you valuable time and money on the production line. A tape application machine is the answer, bringing much-needed speed and precision.

A tape application machine is a piece of equipment that automatically applies adhesive tape to products, such as cardboard boxes or book covers. It ensures the tape is placed accurately and adheres properly every time, boosting efficiency and quality in packaging and printing operations.

Now that we have a basic idea, you probably have more specific questions popping into your head. That’s good! Let’s dig a bit deeper to really understand what tape application involves and explore the different kinds of machines that get the job done right. We’ll break down the details to help you see how this technology fits into your world.

What is tape application, really?

Is the term "tape application" a bit unclear? This uncertainty can slow down your decisions when looking for equipment. Let’s clear it up so you know exactly what we are talking about in the industry.

Tape application is simply the process of putting adhesive tape onto a surface. In our field at Kylin Machine, it specifically refers to applying tape, often heat-activated corner tape, to materials like greyboard or cardboard used for making rigid boxes or book covers.

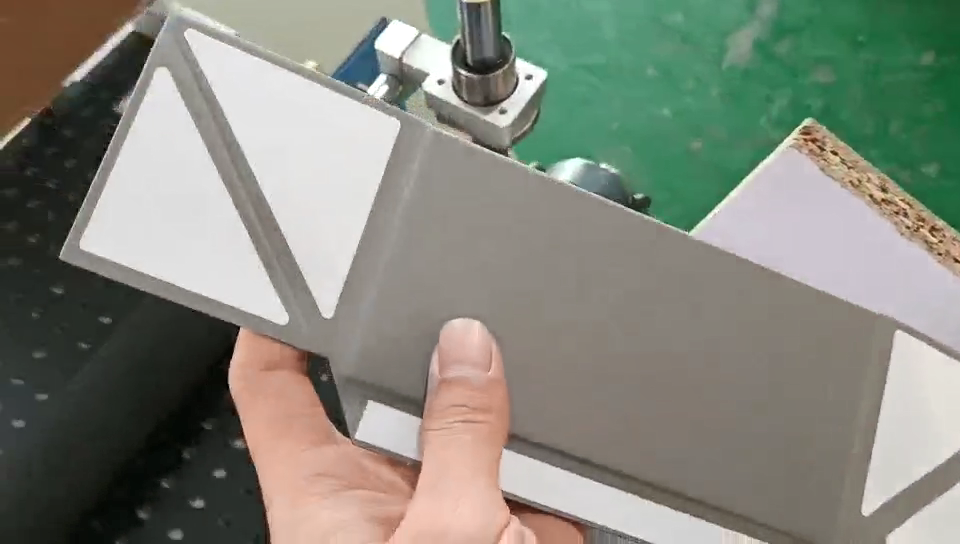

!

Let’s dive deeper into tape application. In my experience working with clients in the packaging and printing sectors, "tape application" usually means using specialized adhesive tape for specific purposes. For rigid box manufacturers, the most common type is corner tape. This is often a heat-sealable tape (like PET tape or kraft paper tape with hot-melt adhesive). It’s applied precisely to the four corners of a die-cut and scored greyboard blank after it’s been formed into a box shape. The tape holds the corners together firmly, giving the box its structure before the final wrapping paper is applied. This step is critical for the box’s strength and final appearance. Manually applying this tape is possible, but it’s slow, requires skill for accuracy, and consistency can be a real challenge, especially at high volumes. Machine application, which is what our machines at Kylin focus on, ensures every corner is taped perfectly, at high speed. This automation directly addresses the pain points of quality control and production speed that many of our customers face.

So, what exactly is a taping machine?

Do you need to speed up your production line? Manual taping often creates a bottleneck and increases labor costs significantly. A taping machine automates this critical task, saving you valuable time and money.

A taping machine, in our context, is industrial equipment specifically designed to automatically apply adhesive tape to items. For businesses in packaging and printing, it handles tasks like sealing the corners of rigid boxes or reinforcing edges quickly and consistently.

Let’s look closer at these tape application machine. When I talk to people in the graphic arts or paper converting industries, the term "taping machine" refers to equipment that takes the manual labor out of applying tape. There are different levels:

- Manual Assist: The operator positions the box, but the machine helps apply the tape.

- Semi-Automatic: The operator might feed the box, but the machine controls the taping cycle.

- Fully Automatic: The machine handles feeding, positioning, taping, and ejecting the box with minimal operator intervention. This is where Kylin Machine puts its focus, integrating advanced technology.

These machines typically consist of a frame, a transport system (like belts or grippers) to move the product, one or more tape heads that dispense, apply, and cut the tape, and a control system (often PLC-based) with sensors. The benefits are clear: greatly increased speed, unwavering consistency (addressing quality control pain points), reduced tape waste, and lower labor requirements. For businesses scaling up or demanding high precision, like many of our customers producing luxury packaging, a reliable automatic taping machine is essential.

| Machine Type | Speed | Consistency | Labor Needs | Investment | Typical Use Case |

|---|---|---|---|---|---|

| Manual Assist | Low | Low-Medium | High | Low | Very small runs, prototyping |

| Semi-Automatic | Medium | Medium-High | Medium | Medium | Small to medium businesses |

| Fully Automatic | High-V.High | Very High | Low | High | Medium to large scale production |

Did the Beatles use a tape machine like ours?

Have you heard people talk about the Beatles and tape machines? It sometimes causes confusion between music recording and industrial taping. Let’s clarify the significant difference between these two types of "tape machines."

No, the tape machines the Beatles famously used were audio tape recorders for capturing music, like machines made by Studer or EMI. These are completely different technologies from the industrial tape application machines we manufacture at Kylin Machine for packaging.

It’s an interesting question that comes up sometimes because the word "tape" is used in both contexts! Let me explain the difference. The machines used in recording studios by artists like The Beatles worked with magnetic tape. This tape stores sound information magnetically. Engineers used multi-track recorders (like the famous Studer J37 4-track at Abbey Road) to capture performances, layer sounds, and create the final music mix. The purpose was purely audio recording and reproduction.

On the other hand, the tape application machines we build at Kylin Machine use adhesive tape. This tape has glue on one side (sometimes heat-activated) and its purpose is physical: to stick things together. In our industry, it’s used for constructing boxes, sealing cartons, or reinforcing book covers. Think of it like a highly automated, precise version of using sticky tape from a dispenser, but designed for high-speed industrial manufacturing. So, while both involve "tape" and "machines," their function, the type of tape, and the industries they serve are worlds apart. We focus strictly on the industrial adhesive tape applicationostpressmachines.com/6-inspiring-design-for-boxes/) application for the packaging and printing world.

How does an industrial tape machine actually work?

Are you curious about the mechanics behind how these machines operate? Understanding the basic steps can help you appreciate their function and choose the right one. We can break down the process simply.

Essentially, an industrial tape machine feeds the product (like a box blank), positions it accurately, dispenses and applies the adhesive tape with controlled pressure, cuts the tape cleanly, and then moves the finished item out. Sensors and controllers manage this sequence.

Let’s walk through the typical process of an automatic corner taping machine, like the ones we design at Kylin Machine for rigid box production. First, the flat, die-cut greyboard blank is usually formed into a basic box shape (often by a separate forming station or manually) and then fed into the taping machine. Sensors detect the box’s arrival. Precision guides or grippers then position the box accurately under the first tape head – alignment is critical for quality. The tape head rapidly descends, dispenses a specific length of heat-activated corner tape, presses it firmly onto the corner using heat and pressure to activate the adhesive, and then a sharp blade cuts the tape cleanly. The machine rotates the box or moves it to the next station to repeat the process on the remaining corners. Finally, the fully taped box structure is ejected onto a conveyor belt, ready for the next production step, like wrapping. The whole process is controlled by a PLC (Programmable Logic Controller) that sequences the motors, heaters, cutters, and reads sensor inputs to ensure speed and repeatability. This automation directly solves pain points related to inconsistent quality and slow manual labor. Our R&D team constantly works on improving the precision and reliability of these mechanisms.

Conclusion

In short, tape application machines are essential tools in modern packaging and book production. They deliver speed, consistency, and quality, helping businesses like yours reduce costs and operate more efficiently.

发表回复