What raw material is required to start a paper bag business?

Starting a paper bag business feels straightforward, right? But choosing the wrong raw materials can sink your quality and profits fast. Let’s explore exactly what you need to succeed.

The core raw materials are paper (like Kraft or art paper), adhesives for assembly, and printing inks for branding. The specific types and quality hinge on the bag’s purpose and desired appearance.

Understanding the basics of raw materials is step one. It ensures you build your paper bag business on a solid foundation. But getting the specifics right is key to avoiding costly mistakes and producing bags your customers will love, encouraging repeat business. Let’s dive deeper into each material type.

What are the raw materials for paper bags?

Thinking any old paper will work for your bags? Using unsuitable paper leads to bags that tear easily or drives up your costs unnecessarily. Understanding the right paper types is fundamental.

The primary raw material is paper, often Kraft paper (brown or white) known for strength, or various coated/art papers for better print quality. Adhesives (glue) and printing inks are also vital components.1!

Let’s break down these materials further. The choice of paper is probably the most critical decision. Kraft paper is a popular choice due to its durability and relatively low cost. You’ll find it in both virgin (stronger) and recycled variants, and it can be bleached (white) or unbleached (brown). The weight, measured in GSM (grams per square meter), is crucial. For basic shopping bags, you might use 100-150 GSM, while luxury bags might demand thicker paper, sometimes up to 350 GSM, for a premium feel and extra strength1. Art paper or coated papers offer a smoother surface, ideal for high-quality printing and finishes. Then come the adhesives. Usually, water-based glues are used for side seams and bottoms, chosen for their bonding strength and drying speed, compatible with machine processes. Finally, inks are needed for branding. Water-based inks are common due to environmental considerations, especially for food packaging, but the choice depends on the printing process and desired visual effect. Don’t forget handle materials – twisted paper, cotton ropes, or ribbons are common additions.

What are the materials needed to make a paper bag?

You’ve sourced your paper, but is that everything? Forgetting essential components like the right glue or handle attachments can completely undermine your finished product. Let’s list all the materials you’ll need.

You require paper rolls (selected by type and GSM), strong adhesives for seams and bottom closures, printing inks for logos and designs, and potentially materials for handles like twisted paper cords or cotton ropes.

Looking at this from a production standpoint helps clarify things. First, your paper rolls arrive. You need procedures for quality checks – is the GSM correct? Are there defects? Proper storage is important to prevent damage. Next, adhesives. The type matters (water-based, hot melt), but so does the application method, which often depends on your machinery. Ensuring the correct amount is applied and allowing proper drying or curing time is vital for bag integrity. For inks, you’ll consider the printing method (flexography is common for bags) and color matching. Consistency is key for brand representation. Environmental regulations might also dictate ink choices. Handles are often a separate component. They need to be attached securely, sometimes requiring reinforcement patches inside the bag opening to prevent tearing under load. Beyond these core items, you might need optional materials like cardboard base inserts for stability, eyelets for ribbon handles, or even special coatings or laminations for a unique finish or barrier properties2. Each material requires careful sourcing and quality control.

How to start a paper bag business?

Knowing the raw materials is just the start, isn’t it? Jumping in without a solid plan, the right equipment, or market understanding often leads to disappointment and financial loss. Here’s a basic roadmap.

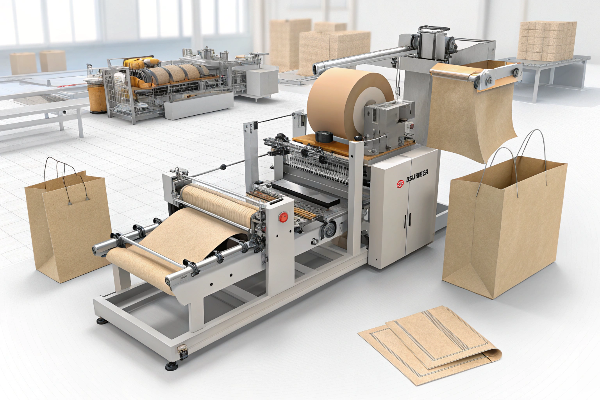

Beyond materials, starting requires a solid business plan, thorough market research, dependable machinery like automatic paper bag makers, trained staff, and a clear sales and distribution strategy.

So, you want to turn those raw materials into a thriving business. First, craft a Business Plan. This involves analyzing your target market (retail stores, restaurants, promotional events?), understanding competitors, and creating realistic financial projections. You’ll need to handle the Legal side: business registration, permits, and compliance with local regulations. Finding a suitable Location with enough space for machinery, storage, and operations is crucial. Now, the big one: Machinery. This is where we at Kylin Machine come in. Choosing the right paper bag making machine is critical. You need equipment that’s efficient, reliable, and matches your production volume needs. Think about speed, precision, and the types of bags you want to make (flat bottom, square bottom, handles, etc.)1. Investing wisely here helps avoid many common pain points like poor quality control or production bottlenecks3. Reliable Sourcing for your paper, adhesives, and inks is non-negotiable. Consistent quality and supply are vital. You’ll also need Staffing – skilled operators for the machines, maintenance personnel, and people for sales and administration. Finally, develop your Marketing and Sales strategy. How will you reach your target B2B customers? Building relationships is key in this industry.

What is the raw material for paper packaging?

We’ve focused on bags, but is ‘paper packaging’ much broader? Thinking only about bags limits your understanding of the market and potential opportunities available with different paper materials. Let’s look at the wider picture.

Paper packaging primarily uses paper and paperboard made from wood pulp (virgin or recycled). Key materials include Kraft paper, various paperboards (like boxboard or chipboard), and corrugated board, depending on the specific packaging form.

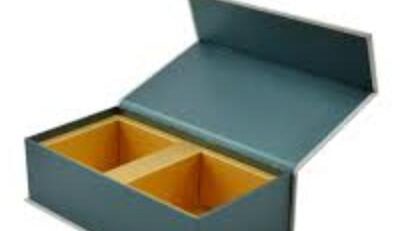

Paper packaging is a diverse field. While paper bags use materials like Kraft and art paper, other forms rely on different paper-based materials. Paperboard is thicker and stiffer than paper. Examples include Folding Boxboard (FBB), often used for food and cosmetic cartons, Solid Bleached Sulphate (SBS) for high-quality graphics packaging, and various recycled grades like Chipboard. These are the base materials for folding cartons and setup boxes (rigid boxes)4. Corrugated Board, made by gluing fluted paper (medium) between linerboard sheets, is the standard for shipping boxes due to its strength and cushioning properties. The raw material source – wood pulp – can be virgin (from trees) or recycled (from waste paper), impacting both cost and sustainability credentials. Often, coatings (like clay for printability) or laminates (like plastic films for moisture barriers) are applied to these base materials to enhance performance or appearance. Understanding this broader range is important because different packaging types require different machinery – something we specialize in at Kylin Machine, covering equipment for rigid boxes and more, not just bags4. The choice of raw material fundamentally influences the required converting technology.

Conclusion

Essentially, starting a paper bag business requires paper, adhesives, and inks. But success truly depends on selecting the right quality materials and investing in efficient, reliable machinery to transform them profitably.

-

Based on specifications listed in Reference Material 2 for a Shopping Bag Machine, mentioning paper types (Art Paper, Kraft Paper) and thickness ranges (100-350gsm). ↩ ↩ ↩

-

Reference Material 2 mentions potential paper characteristics or treatments like "OPP, gloss oil, second oil, optical cement," which likely refer to finishes or laminations applicable to certain paper types used in bag making for enhanced appearance or properties. ↩

-

Reflects customer pain points mentioned in Reference Material 5, such as concerns about equipment performance vs. cost, technology updates, and quality control. ↩

-

Derived from Reference Material 1 and 3, which state Kylin Machinery serves the Paper Converting industry and manufactures machinery for rigid boxes, round boxes, collapsible boxes, beyond just bags. ↩ ↩

发表回复