What is the best binding method for hardcover books?

Choosing the right binding can feel complex. You want your hardcover books to look professional and last long. Poor binding leads to pages falling out, ruining the reader’s experience.

For durability and a premium feel, sewn case binding is widely considered the best method for hardcover books. This involves sewing the book’s pages together in sections before attaching them to a rigid cover.

Understanding the different binding options helps you make the best choice for your project. Let’s explore why certain methods stand out and what goes into creating a truly high-quality hardcover book, so you can ensure your final product meets expectations.

What is the best binding for a hardcover book?

Are you confused about which binding truly makes a hardcover book stand out? Choosing incorrectly can affect the book’s feel, durability, and how easily it opens.

The best binding for a high-quality hardcover book is typically section-sewn case binding. It offers maximum durability, allows the book to lay flatter when open, and provides a classic, professional appearance expected of hardcovers.

When we talk about hardcover binding, we usually mean “case binding.” This is where the inside pages (the “book block”) are attached to a separate, rigid cover (the “case”). But how the pages within that block are held together makes a big difference. The two main methods are sewing and adhesive binding (often called “perfect binding” even when used for hardcovers).

For true quality and longevity, sewing is superior. Here’s a breakdown:

- Section Sewing (or Smyth Sewing): Pages are printed on large sheets, folded into sections (called signatures), and then sewn through the fold of each section. All sections are then sewn together to form the book block. This creates a very strong, flexible spine.

- Adhesive Binding (Perfect Binding): The edges of the collated pages are roughed up, and a strong, flexible adhesive is applied to hold them together before attaching them to the case. While common for paperbacks and some lower-cost hardcovers, it’s generally less durable than sewing, and pages can potentially detach over time, especially with heavy use.

Here’s a simple comparison:

| Feature | Section Sewn Case Binding | Adhesive (Perfect) Case Binding |

|---|---|---|

| Durability | Very High (Strongest) | Moderate to High |

| Lay Flat | Good (Often lays flatter) | Moderate (Can be stiff) |

| Appearance | Premium, Traditional | Good, Common |

| Cost | Higher | Lower |

| Best For | Textbooks, library books, keepsakes | Novels, trade books |

In my experience working with clients in the bookbindery industry, those producing premium products always opt for sewn binding. The investment in quality machinery for sewing and casing-in pays off in customer satisfaction and the product’s lifespan. Our Kylin machines are designed to handle these processes with the precision needed for top-tier results.

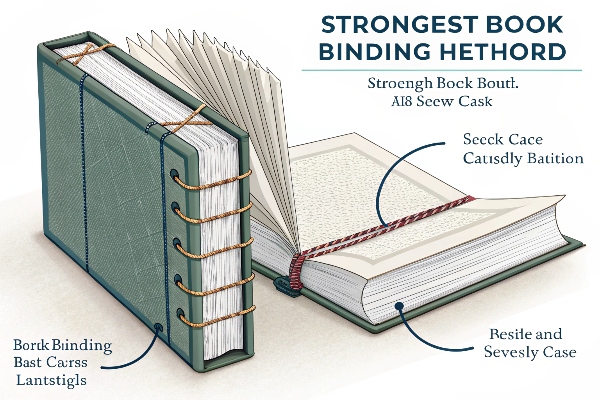

What is the strongest book binding method?

Worried about books falling apart after just a few reads? Weak binding can lead to customer complaints and damage your reputation, especially for books meant to last.

Section-sewn case binding is generally recognized as the strongest and most durable book binding method, especially for hardcover books. The thread physically locking the pages together provides unmatched longevity.

The strength comes directly from the construction method. Imagine trying to pull apart pages held only by glue versus pages physically stitched together with thread – the stitches provide far greater resistance. In section sewing, multiple threads pass through the folds of each signature and link the signatures together. This creates a robust book block that can withstand years of opening, closing, and page-turning.

Factors contributing to the strength include:

- Thread: Using strong, appropriate thread is crucial.

- Sewing Technique: Proper tension and stitch placement ensure signatures are securely linked.

- Spine Preparation: After sewing, the spine is often glued for added stability, rounded, and backed [^3] [^5]. Rounding gives the spine its characteristic convex shape, while backing creates a shoulder or hinge along the spine edges. This helps the book open properly and distributes stress, further enhancing durability. Our specialized machines, like book spine rounding and backing machines [^3], ensure this critical step is done accurately.

- Case Attachment: Securely attaching the book block to the rigid cover using strong endpapers and adhesive is the final step in ensuring overall strength.

While perfect binding has improved with modern adhesives, it fundamentally relies on glue adhering to the edge of each page. Sewn binding anchors pages from within the fold. This mechanical lock makes it inherently more resistant to pages loosening or falling out, making it the preferred choice for archival quality, library editions, textbooks, and any book intended for heavy or long-term use. Investing in machinery that executes these sewing and casing-in steps precisely is key to achieving this superior strength.Which type of binding is best for books?

Feeling overwhelmed by all the different ways books can be bound? Choosing the wrong type can make a book impractical for its purpose or give it an unprofessional look.

There isn’t one single "best" binding for all books; the ideal choice depends heavily on the book’s purpose, page count, budget, and desired lifespan. However, for durability and quality, case binding is often preferred for hardcovers.

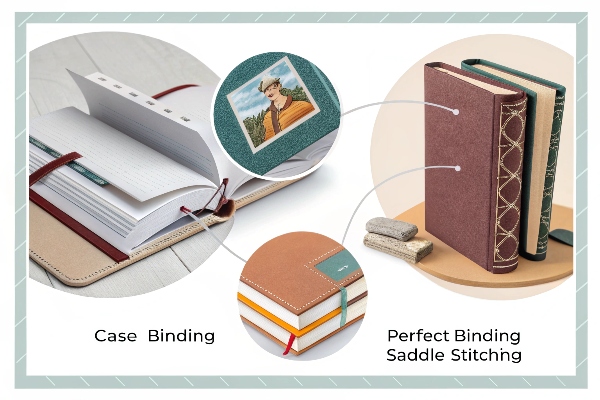

Matching the binding style to the book’s function is key. Think about how the book will be used: - Short-term use, low page count (e.g., brochures, magazines): Saddle stitching (stapling through the fold) is economical and allows pages to lay flat, but isn’t very durable for thick publications.

- Manuals, notebooks, reports: Spiral binding (plastic coil) or Wire-O binding (metal loops) allow books to lay perfectly flat or fold back on themselves, which is great for reference materials. Durability varies.

- Paperbacks, trade books: Perfect binding (adhesive) is cost-effective for mass production and offers a clean, square spine. Durability is good for typical reading use but less than sewn methods.

- Hardcovers, textbooks, library books, premium editions: Case binding (sewn or adhesive book block attached to a rigid cover) offers the highest durability and a professional, lasting appearance. Section-sewn case binding represents the top tier in this category.

Here’s a quick guide:

| Binding Type | Typical Use Case | Lay Flat | Durability | Cost | Appearance |

|---|---|---|---|---|---|

| Saddle Stitch | Booklets, magazines | Yes | Low | Very Low | Simple |

| Spiral / Wire-O | Manuals, notebooks, calendars | Yes | Moderate | Moderate | Functional |

| Perfect Binding | Paperbacks, journals, catalogs | Moderate | Good | Low-Mod | Clean, Square Spine |

| Case Binding (Sewn) | Hardcovers, textbooks, keepsakes | Good | Very High | High | Premium, Durable |

So, while perfect binding might be "best" for an affordable novel, and spiral binding "best" for a cookbook, section-sewn case binding is generally considered the "best" choice when the priority is creating a durable, high-quality, long-lasting hardcover book. Achieving this level of quality consistently relies on precise machinery for each step, from preparing the book block to creating and attaching the case.

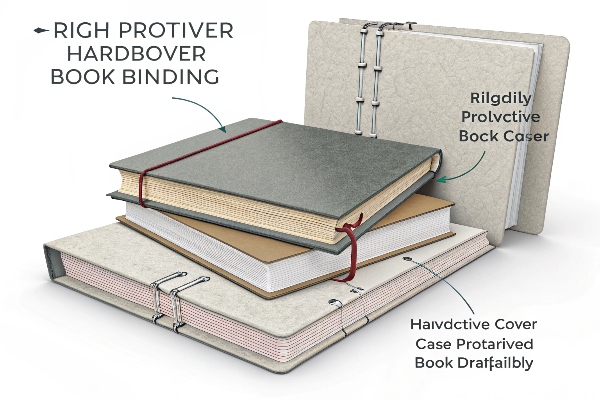

What type of binding is hardcover?

You often hear the term "hardcover," but what exactly does that mean in terms of how the book is constructed? It’s easy to assume all hardcovers are made the same way, but the process defines the quality.

Hardcover binding is technically known as "case binding." This process involves creating a rigid protective cover (the "case") separately from the book’s pages (the "book block") and then attaching the two together.

Let’s break down the essential steps involved in creating a standard hardcover book using case binding:

- Creating the Book Block: The pages of the book are printed, folded into signatures (groups of pages), and collated in the correct order. These signatures are then joined together, ideally by sewing through the folds (section sewing) for maximum durability, or sometimes by using adhesive (perfect binding). The spine might then be prepared further, potentially involving gluing, rounding, and backing [^3] [^5] to give it shape and strength.

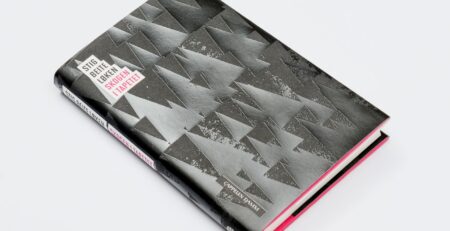

- Making the Case: This is the rigid outer cover. It’s constructed separately using binder’s board (thick, stiff cardboard) cut precisely to size for the front cover, back cover, and spine piece. These board pieces are glued onto a larger sheet of covering material (like cloth, paper, or leather). The edges of the covering material are then carefully folded over the boards and glued down – a process called "turning in." Sometimes, corners are rounded using specialized machines for a different aesthetic [^1] [^2] [^4] [^6].

- Casing In: This is the final assembly step. Adhesive is applied to the endpapers (the sheets glued to the inside of the cover and the first/last pages of the book block). The book block is then carefully positioned and pressed onto the case, permanently joining them together.

The quality of a hardcover book depends heavily on the precision of each step. Using specialized machinery, like the hard cover making machines and rounding machines we produce at Kylin Machine 1 2 3 4 5, ensures accurate board cutting, consistent glue application, neat edge turning, and precise alignment during casing-in. This results in a durable, square, and professional-looking final product that meets the high standards expected in the graphic arts and bookbindery industries.Conclusion

In summary, section-sewn case binding stands out as the best and strongest method for durable, high-quality hardcover books. Achieving this requires precision, best supported by reliable, specialized machinery.

-

Kylin Machine, bible book gilding and book cover machine ↩

-

Kylin Machine, bible book gilding and book cover machine ↩

-

Kylin Machine product listing ↩

-

Kylin Machine, Ky-560 hardcover caseing in machine ↩

-

Kylin Machine, bible book gilding and book cover machine ↩

发表回复