Sleeve box making process

The slipcase box is composed of two layers of board formed to make double-thick walls on the top, bottom and spine, with a one-piece outer wrap that allows for continuous artwork. Most commonly used in the publishing industry for special edition releases, box sets, CDs and DVDs, or storage for reference materials, the Slipcase will not only secure your product for longevity, adding value, but also provides a canvas for unique embellishments that will distinguish your work on the shelves. Slipcases also make a great home for brochures or direct mail promotional items! Set your collectors edition apart, or draw attention to your pharmaceutical binders with an eye-catching Slipcase!

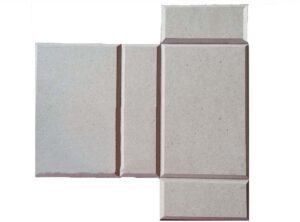

The first steps to make slipcase box is to form the side box with luxury cover sheets,

without sealing the corner of boxes, the new slipcase box maker Ky-280 is forming the boxes, just like fold the hard cover case.

Online Video

Slip case boxes is a widely liked category of packaging used to give protection and an enticing look to the products. These boxes make the product packaging quite inspiring and helps brands attracting more customers. The most common of these boxes is the slipcase book boxes which book manufacturing companies and individuals use to encase different kinds of books. The design and material of these boxes protect the books’ covers and pages from getting worn out. For bibliophiles, having these books serve dual purposes, they keep their favorite books intact for years and help them organizing their collection. Slip cases can be padded from inside and you can have accessories like ribbons attached to them. However, designing and printing luxury slip case rigid boxes requires professional expertise.

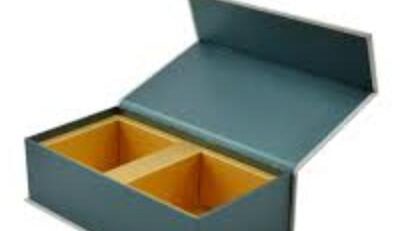

Second step to use the fold and closing machine Ky-238, to folding and close the top edges, for complete end process of the slipcase box.

Online Video

发表回复